Purchasing depackaging separation and materials handling equipment can be an overwhelming task. There are a lot of manufacturers to choose from, so it can be hard to narrow down your selection. The best thing to do is to read as much as you can, and then narrow down your choices.

In this article, we have selected the Smicon and Dominator Depackagers to describe and discuss. Read on to find out more about the products offered by those two manufacturers.

Depackaging Technology is Cost Effective and Green

Using a depackager to transform food waste into compost can be a cost effective and green way to dispose of your kitchen scraps. However, depackagers are not for everyone. Some municipalities have banned the recycling of food scraps, while others are hesitant to adopt the process. A new generation of depackagers has been developed to take the sting out of the process.

https://player.stoodaio.host/embed/SCHoEueB8fCUUamhaPO2oUvz?autoplay=0&controls=0&preview=0&color=#ffffff

A new study found that the best depackagers on the market could save businesses as much as 25 percent of the cost of sending their waste to a conventional facility. The technology has been around for several years, but it’s only recently that the industry has embraced it in earnest.

Some state regulators are already proposing regulations for large food waste generators.

The Smicon Depackager

Increasingly, state-of-the-art depackaging separation & materials handling equipment are being utilized for organic waste processing. These systems are used to depackage dry and wet organic waste for reuse, composting, anaerobic digestion, and animal feed. These systems can also open containers of food and liquid products and break up a variety of packages, including wax-coated plastics, aluminium cans, and ready-meal containers.

The Smicon SMIMO30 unit combines proven European technology with U.S.-made parts to depackage packaged food waste with a 99% efficiency rate. The unit can produce slurry for animal feed, composting, and anaerobic digestion. The unit includes a digestate holding tank, a patented debagger, and an auger that transfers digestate to a disposal tank.

Smicon depackaging separation and materials handling equipment is suited for the processing of food waste from commercial businesses, hospitals, schools, universities, and other institutional settings. The systems also can be used to process waste from the hospitality industry.

The Dominator Depackaging Machine

Whether you are a commercial business looking to cut down on costs, or an individual who wants to keep your home clean, the Dominator Depackaging Machine can help you get the job done. By depackaging food and other liquids, you can separate the liquid and food into recyclable materials. These materials can then be used for composting or recycling.

Separate food and liquid from outer packaging

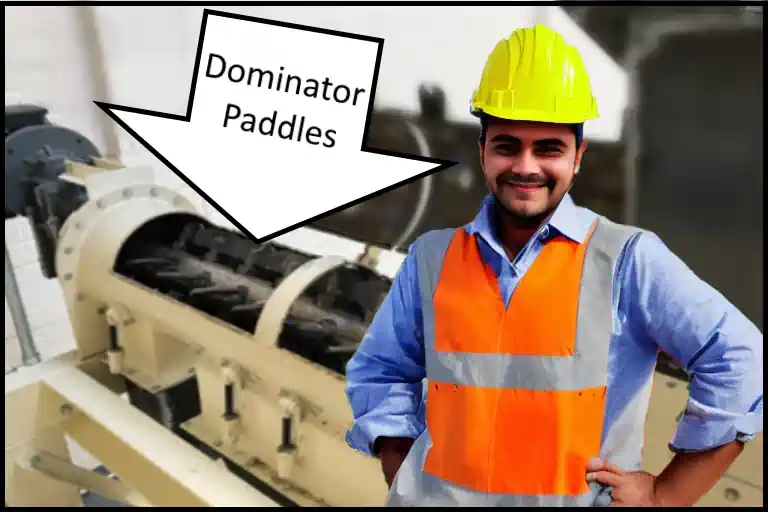

Whether you need to separate food and liquid from outer packaging or dry waste from wet packaging, you should check out the Dominator Depackaging Machine. This system utilizes a centrifugal force to force materials through a mesh screen. This allows the separation of food and liquid from outer packaging, as well as the recovery of metal and liquid content.

There are two different Dominator models: one for dry waste and the other for wet waste. Both models have screen sizes that can be adjusted to match the finished product. They are available in stainless steel and mild steel models. They come with a variety of motors ranging from 15 to 75 kilowatts. They are designed for commercial and residential applications.

The Dominator Depackaging Machine also has a barrel that can be used to help with wet waste. It can also be fitted with wastewater injection points.

Recycle food, garden waste, and other organic waste

Designed to depackage waste, the Dominator Depackaging Machine is an industry innovation that enables recyclers to separate plastic and paper packaging into organics. It can depackage a range of materials, including food, garden waste, and municipal waste.

The machine works by using centrifugal and mechanical forces to depackage waste. The machine is designed to deal with a range of materials and can depackage tin cans, tetra paks, plasterboard, and bakery waste. Its screen sizes are adjusted to match the requirements of the finished product.

The device uses a motor to drive a solid steel shaft lined with paddles. The paddles spin at 400 rotations per minute and break the packaging into pieces.

Recycle plastic bottles

Developed in 1992 following an accident at an animal feed factory, the Dominator depackaging machine is an effective way to recycle plastic bottles and other packaging. It works by breaking down the packaging through mechanical and centrifugal forces. It is designed to depackage wet and dry waste, including food, pharmaceutical, and municipal waste. It can also handle tin cans and plasterboard.

The Dominator Depackaging Machine is installed at a pharmaceutical waste recovery factory. The unit is capable of recycling 99% of the material. It can depackage food waste, including orange juice from different size cartons. The machine is made of mild steel and can be fitted with a wastewater injection point. The Dominator can also handle wet waste, including carbonated drinks and aerosol cans.

Recycle tin cans

Using a Dominator Depackaging Machine, you can recycle your tin cans and many other kinds of packaging. The device works by applying centrifugal forces and a screen to separate the contents of packaging. The unit is also useful for deboxing aluminium blister packs from cardboard boxes.

The device was designed to be gentler on the product it was processing. This makes it a good choice for small businesses, as well as for large companies that generate lots of waste. It also comes in a variety of sizes to suit your budget and your requirements. The machine is available in stainless steel or mild steel, with a motor of up to 75 kilowatts. The unit can also be fitted with a barrel to assist with wet waste. The machine is able to process municipal waste, food waste, and pharmaceutical waste, among other things.

Recycle plasterboard

Using Dominator depackaging machines, you can recycle plasterboard and recover the plasterboard backing. These devices can be used in all industries. This innovative installation can also reduce the amount of waste going to landfills. This can save significant costs. The apparatus can also be used in-situ to treat waste plasterboards, saving the costs associated with transporting waste to a fixed station.

Typically, plasterboards are made of gypsum that is between two layers of paper. Plasterboards are generally used for non-load-carrying dividing walls, such as walls between rooms in a house. Plasterboards are very easy to mount and are very fast to dry. These materials are inexpensive. However, the cost of disposing of the waste is high. This is especially true when you consider that the cost of storing paper in a landfill is extremely high.

Conclusion – Smicon and Dominator Food Waste Separation Technology

The recovery of nutrients from food waste is a major focus within the circular economy. Food waste recycling can help to close the loop on food production and consumption and reduce the pressure on finite resources.

There are many different types of food waste recycling machines and equipment on the market, each with its own advantages and disadvantages. We selected just two Smicon and Dominator food waste separation technology to discuss in this article.

Some other leading manufacturers and suppliers of food depackaging machines include Recycla, FoodCycle, and RealWorld Recycling.

If you are interested in purchasing a food waste recycling machine?

If so it is important to compare the different models on the market. Select the one that makes profitable recyclable profits, in addition to high value and purity organic pulp much sought after by biogas plant operators, and best suits your needs. You should no longer be content with old technology and having to send your output to landfills.

TAGS: DEPACKAGING SEPARATION, DOMINATOR DEPACKAGER, SMICON DEPACKAGER

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.