The effective removal of plastic contamination from organic waste is critical for the sustainable management of organic resources, particularly when used as feedstock in anaerobic digestion (AD) plants and composting facilities. These processes offer significant environmental benefits, including renewable energy production and soil fertility improvement. However, plastic contamination poses a severe challenge, undermining the quality of the output, whether biogas, digestate, or compost. This article delves into the various methods and technologies employed to remove plastic contaminants from organic waste, focusing on their applications, effectiveness, and challenges.

Key Takeaways

- Sustainability Priority: Anaerobic digestion is generally more sustainable than composting, as it facilitates energy extraction from organic waste while also producing digestate for soil amendment.

- Manual and Mechanical Methods: The primary methods for plastic removal are manual picking and various mechanical processes, including screening machines, separators, and de-packagers.

- Effectiveness Varies: The efficiency of these methods varies widely depending on the technology used, the nature of the feedstock, and the stage of processing.

- Challenges: Costs, safety concerns, and technological limitations are significant challenges faced by operators in removing plastic contamination effectively.

Methods for Removing Plastic Contamination

1. Manual Picking

Manual picking is one of the oldest and most straightforward methods for removing plastic contaminants. Workers manually sort through organic waste, removing large, identifiable pieces of plastic and other non-organic materials. This method is labour-intensive and often used in conjunction with other technologies to enhance the overall effectiveness of contamination removal.

Advantages

- Simplicity: Requires minimal technology and can be implemented at any facility.

- Targeted Removal: Effective for large, easily identifiable contaminants.

Disadvantages

- Labour-Intensive: Requires significant human labour, making it costly and potentially inconsistent.

- Limited Effectiveness: Not effective for smaller or less visible plastic particles.

- Unhealthy Working Conditions: Workers must work in dusty air and will ingest plastic.

2. Mechanical Screening

Mechanical screening is a more advanced technique, involving the use of machines to sift and sort organic waste based on particle size. The most common screening machines include:

- Wind Sifters: Use air currents to separate lighter plastic materials from organic waste.

- Trommel Screens: Rotating cylindrical drums that separate materials based on size.

- Star Screens: Rotating rubber stars that sort material by size and break up clumps of waste.

| Screen Type | Functionality | Typical Opening Size |

|---|---|---|

| Wind Sifters | Separates light materials like plastic films | Various settings |

| Trommel Screens | Separates materials based on rotational tumbling | 3 mm to 100 mm |

| Star Screens | Breaks up material while separating by size | 6 mm to 9 mm |

Advantages

- Automation: Reduces the need for manual labour.

- Consistent Output: Provides a more uniform feedstock for further processing.

Disadvantages

- Initial Cost: High capital investment required.

- Inefficiency with Microplastics: May not effectively remove small plastic fragments.

3. Separators

Separators use physical principles such as buoyancy and shear force to differentiate between organic material and contaminants. Common types include:

- Hydropulpers: Mix waste with water, separating plastics that float from heavier materials that sink.

- Grit Removal Systems: Specifically designed to remove heavy particles like glass and sand from organic waste.

Advantages

- Effective Separation: Good for separating a wide range of contaminants.

- Scalable: Can be adjusted to handle different volumes of waste.

Disadvantages

- Water Usage: Some systems require significant amounts of water.

- Complexity: More complex to operate and maintain than other methods.

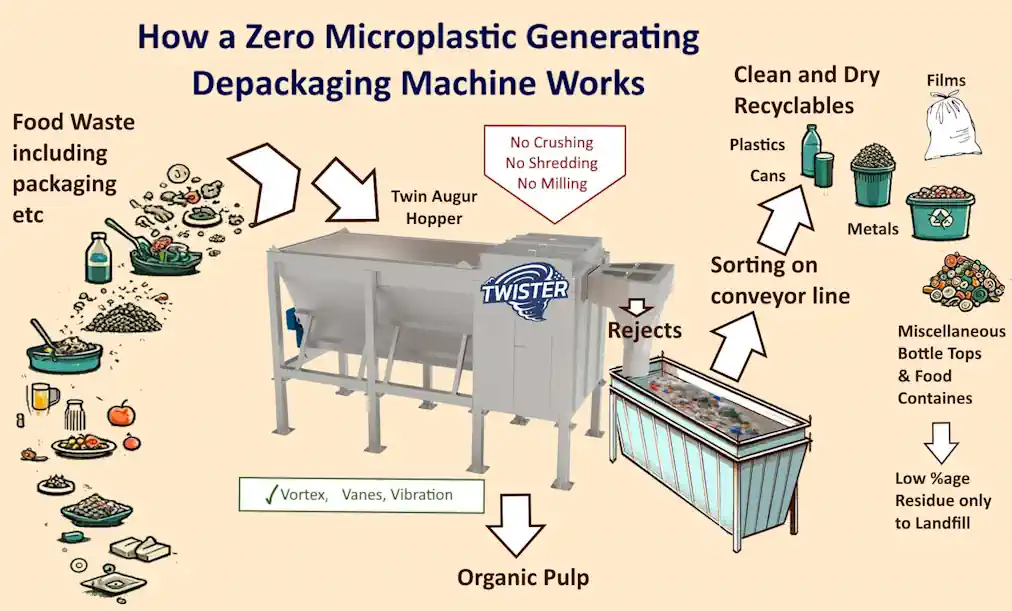

4. De-Packagers

De-packagers are specialized machines that separate organic material from its packaging using a combination of mechanical actions such as shearing, hammering, and pressure application. These systems are particularly useful in preprocessing food waste before it is fed into AD plants or composting facilities.

| De-Packaging Action | Description | Common Applications |

|---|---|---|

| Shearing | Cuts and separates packaging | Packaged food waste |

| Hammering | Breaks open packaging to release contents | Hard or rigid packaging |

| Pressing | Compresses waste to squeeze out organics | Mixed organic and inorganic waste |

Advantages

- High Throughput: Capable of processing large volumes of waste quickly.

- Versatility: Can handle various types of packaging, including plastic, cardboard, and metal.

Disadvantages

- Cost: High initial investment and operational costs. However, for the equipment that achieves truly clean and dry rejected plastics without producing microplastic/ nanoplastic these costs can be more than offset by the sales value of the plastic-free pulp. Additionally, landfill disposal cost savings can be very high.

- Potential for Microplastic Generation: The mechanical forces used can fragment plastics, leading to microplastic contamination.

Challenges and Effectiveness

The effectiveness of plastic contamination removal techniques varies based on the specific technology and method used. Despite the advancements in mechanical separation, no single method is 100% effective, and microplastics often remain in the final products, whether compost or digestate.

Multiple methods are often used in tandem to increase overall effectiveness. For example, pairing manual picking with mechanical screening can target different sizes and types of plastic contaminants, thereby improving the purity of the feedstock.

Prevalence of Contaminant-Removal Techniques

Recent surveys reveal that different regions and facilities adopt varying approaches to contamination removal, with factors such as local regulations, waste composition, and available technology influencing their choices. Notably:

- California: 32% of large composting facilities use picking stations, and 50% utilize other mechanical equipment.

- Washington State: Operators have expressed reluctance to invest in new, unproven technologies due to cost concerns and uncertain effectiveness.

- U.S. Anaerobic Digesters: 38% of facilities reported using some form of preprocessing, with de-packaging being more common in stand-alone AD facilities.

Conclusion

Removing plastic contamination from organic waste is a critical step in ensuring the sustainability and effectiveness of anaerobic digestion and composting processes. While various manual and mechanical methods are available, each has its own strengths and limitations. The most sustainable approach is to prioritize anaerobic digestion over composting, as it not only treats organic waste but also generates renewable energy.

For facilities and waste management professionals seeking to optimize their operations, the careful selection and combination of contamination removal methods are essential. Continued innovation and investment in advanced technologies will be vital in overcoming the current challenges and improving the overall purity of organic waste feedstocks.

To explore advanced technologies for waste separation and to find the best solutions for your facility, visit Twister Separator.

FAQs

- What is the most effective method for removing plastic contamination from organic waste?

- There is no single most effective method. A combination of manual picking and mechanical screening, such as using de-packagers, is often the most effective.

- Beware of any process that uses particle size reduction, such as milling, crushing and pulverising as these simply hide the plastic by making it less visible. Worse still, they create microplastic and nanoplastic and these once in the environment have been shown to reduce cellular viability and fertility levels. Small microplastic and nano-plastic is now in all our bloodstreams although little is known about its effect on humans.

- Why is anaerobic digestion preferred over composting for organic waste treatment?

- Anaerobic digestion is more sustainable because it not only treats organic waste but also generates renewable energy in the form of biogas.

- Can de-packagers completely eliminate plastic contamination?

- No, while de-packagers are effective at removing most plastics, they can also create. microplastics, which may remain in the final product.

- Are mechanical separation machines expensive to operate?

- Yes, mechanical separation machines require a high initial investment and can have significant operational costs, but when they produce clean and dry, practically intact-item plastic output can quickly pay for themselves in eliminating landfill costs, and plastic free organic pulp also commands a good sales value for biogas plant use.

- What happens to the plastic removed from organic waste?

- Removed plastic has until recently typically been sent to landfills or, in some cases, to energy recovery facilities where it is incinerated to generate electricity. However, the Twister Depackaging System by Drycake is an example of a depackager that pays for itself and more, by producing clean separation allowing the plastic to be recycled.

Article Source: US EPA “Emerging Issues in Food Waste Management Commercial Pre-Processing Technologies”. Researched from Emerging Issues…

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.