Getting the best food waste depackaging systems is important for any business that needs to separate waste. It can help you save time and money while also helping you to recycle the waste.

As the world’s population continues to grow, so does the amount of food waste generated each day. It is estimated that by 2050, the world will generate 2.1 billion tonnes of food waste annually.

While some food waste can be composted or fed to animals, the majority of it ends up in landfills where it decomposes and emits methane, a greenhouse gas that is 28 times more potent than carbon dioxide.

One way to reduce the amount of food waste going to landfills is to depackage it before it is sent for recycling. Depackaging food waste refers to the process of removing packaging material, such as plastics, metals, and glass, from food waste.

There are a number of food waste depackaging systems available on the market, ranging from small-scale to industrial-scale. In this blog post, we will take a look at some of the most popular food waste depackaging systems which have been available for some time and explore the benefits of each.

Doda BioSeparator

Among the numerous food waste depackaging systems on the market, the Doda BioSeparator stands out. This small, but mighty machine is ideal for composting, and can help remove contaminants and recyclable materials from food waste.

The machine features a vertically configured hammermill that pulverizes waste, and a 0.5-inch screen that extracts organics and recyclable materials. It can process between two and seven cubic meters of waste per hour. It is manufactured from AISI304 stainless steel and can be easily integrated into a composting facility.

Its most noteworthy attribute is the integrated collection tank, which is handy for storing shredded material. The machine is also fitted with a 5.5 KW centrifugal electric shredding pump.

The machine also uses a clamshell scoop to deposit the batches. The “Oh so clever” hopper can be re-purposed for a larger processing capacity. The machine also has a couple of tricks up its sleeve, including the ability to add water to the mix to make a slurry for an AD substrate.

Tiger machine

Designed to remove organic fractions from packaging, the Tiger Depackaging System is an efficient and effective machine. It can be used in a variety of applications. It can be used in anaerobic digestion, composting, and packaging recovery operations.

The Tiger HS 640 is a vertical mill with package-lacerating feed screw augers and a punch-plate screen basket. Its large capacity makes it a great machine for cleaning oversized screened materials. The machine is used for optimizing organic waste cycles in biogas production installations.

Tiger machinery can be used indoors or outdoors. It features a large touchscreen panel and integrated sensors that allow users to manage the main parameters of the machinery. It also interacts easily with external management systems.

The Tiger system can be inserted into existing production lines, or into an upstream refining or composting cycle. It can also be used as a pretreatment system.

Cesaro Mac Import is a company that offers state-of-the-art technological solutions. The company offers a range of integrated waste treatment plants, as well as innovative solutions to complex processing problems.

Doppstadt

Founded in 1965 in Velbert, Germany, Doppstadt is a leading partner in environmental technology. The company focuses on a range of products, including trommel screens, grinders, recycling machinery, and biomass processing equipment. They have customers in 40 countries worldwide. The company’s products are used in many industries, including composting, food waste processing, wood chip production, and recycling.

Doppstadt also manufactures a variety of smaller equipment, including a shredder, a trommel screen, and a composting machine. Aside from producing recycling equipment, the company also contributes to environmental protection, including preserving natural resources. It also manufactures the Tiger Depackaging System, a vertical cyclonic separation machine that uses a series of package-lacerating feed augers to separate packaging from food and the bio-available organic fraction from the rejects.

The Tiger Depackaging System is available in three sizes: a 40 cubic yard/hour unit, a 60 cubic yard/hour unit, and a 100 cubic yard/hour unit. The smaller unit boasts a 60 hp motor, while the larger unit has a capacity of 11 to 16.5 tons/hour.

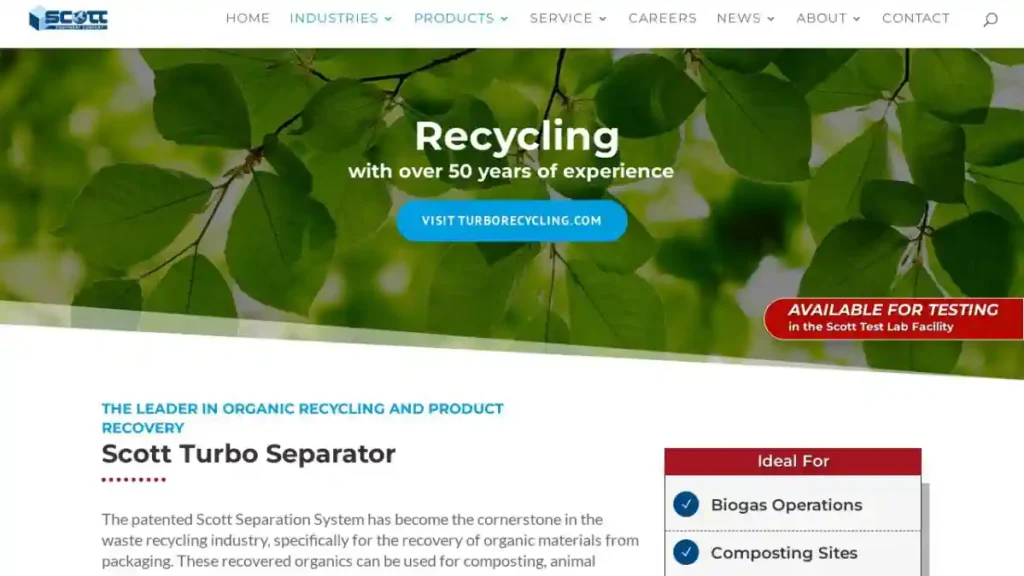

Scott Equipment

Whether you are recycling or processing food waste, you can find the right depackager from Scott Equipment. They offer several different models, including the Turbo Separator, which processes liquid and dry products, and the Twister, which can handle all types of food waste, including boxed and shrink-wrapped food.

Scott Equipment Company is based in Arlington, Minnesota, and is known for its depackagers. The company’s main focus is on industrial food waste and post-consumer waste. They also make custom machinery for companies that have specific needs. They manufacture five different food waste depackagers, ranging in capacity from 2 to 40 tons per hour.

The Turbo Separator system is one of the most efficient and effective depackagers available. It is known for its high uptime, high efficiency, and low maintenance. It also reduces waste disposal costs, especially with mislabeled products. The Turbo Separator is used by various businesses, including E.L Harvey & Sons, Republic Services, and AgChoice.

Scott Equipment also makes the THOR, which is a top-of-the-line organic separation system. The THOR features a 1-inch thick 316 stainless steel shell. Its combination shredder and screen can help you dry food waste for use in composting, as well as slurry it for pumping into low-solids AD systems.

Conclusion

The food waste depackaging market has only recently grown to the point that the equipment suppliers have been able to invest in the specific development of machines designed from the start for food waste processing.

The above well-established manufacturers should always be compared with the better performance of the products offered by the more recent entry companies to the market, before making a purchase. Technology moves on and new ideas have injected greatly improved separation methods into this market in just the last few years.

Companies such as Drycake Twister produce machines that are energy efficient, have a small footprint, don’t use size reduction (which creates a huge amount of hard to clean small plastic pieces), and output clean rejects which can be easily recycled (at a profit) without environmentally damaging water washing of the whole reject stream.

TAGS: FOOD WASTE DEPACKAGING SYSTEMS

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.