Struggling with food waste management? Efficient depackaging technologies help reduce landfill waste and microplastic pollution. This article explains how mechanical separation, particle size reduction, and advanced screening techniques enhance recycling efforts. Get ready to learn more!

Key Takeaways

- Efficient depackaging technologies, like the Depackaging Machine DRM, can process up to 25 tonnes of mixed organics per hour. They ensure high purity separation and reduce landfill waste by separating food from packaging.

- Modern depackaging methods avoid creating microplastics by using less water and energy. Advanced screening techniques filter out tiny particles without breaking them down too much.

- Mechanical separation, with particle size reduction, and advanced milling and shredding, create microplastics and, as a consequence, are no longer acceptable technologies for use in waste sorting and separation lines. These outdated processes improve organic resource recovery but the recycling stream output is dirty, has no use for recycling or energy extraction, and has a highly negative environmental impact.

- Avoiding particle size reduction through the use of low-impact depackaging machines that keep the rejected (non-organic) output as whole as possible makes subsequent waste processing steps of the depackaging machine output, such as smart picking, fully effective. This supports anaerobic digestion and composting better, because with outdated equipment, a dirty reject stream can easily take with it 30% of the organic content, reducing biogas output, while raising landfill use and associated methane emissions.

- Enhanced resource recovery from recyclates such as plastic resins leads to higher income. Efficiently sorted waste allows for generating useful biogas and biosolids for fertilisers, promoting a circular economy where every piece finds a new purpose.

Developed for quarry product processing origin – source of today’s milling and screening

Depackaging technologies started in quarry product processing. Machines used for milling and screening rocks paved the way. These early machines separated materials by size and texture.

Over time, this tech improved to handle waste recycling.

Modern depackaging avoids making microplastics. Special screens filter out tiny particles without breaking them down too much. This reduces harmful pollution in our landfill sites and waterways—keeping the environment safer for everyone.

Avoiding microplastic creation

These technologies can help avoid microplastic creation. They use less water and energy, leading to better separation without breaking down plastics into tiny pieces.

Some machines like the DRM have a high throughput capacity of up to 25 tonnes per hour. This allows for efficient processing of mixed organics, such as food waste, while keeping plastic waste intact.

This method helps prevent the formation of microplastics in our environment.

Key Depackaging Processes

Machines tear open packages, break down items into smaller pieces, and sort materials to reduce waste… This helps avoid creating microplastics while recovering useful resources from waste.

Mechanical separation

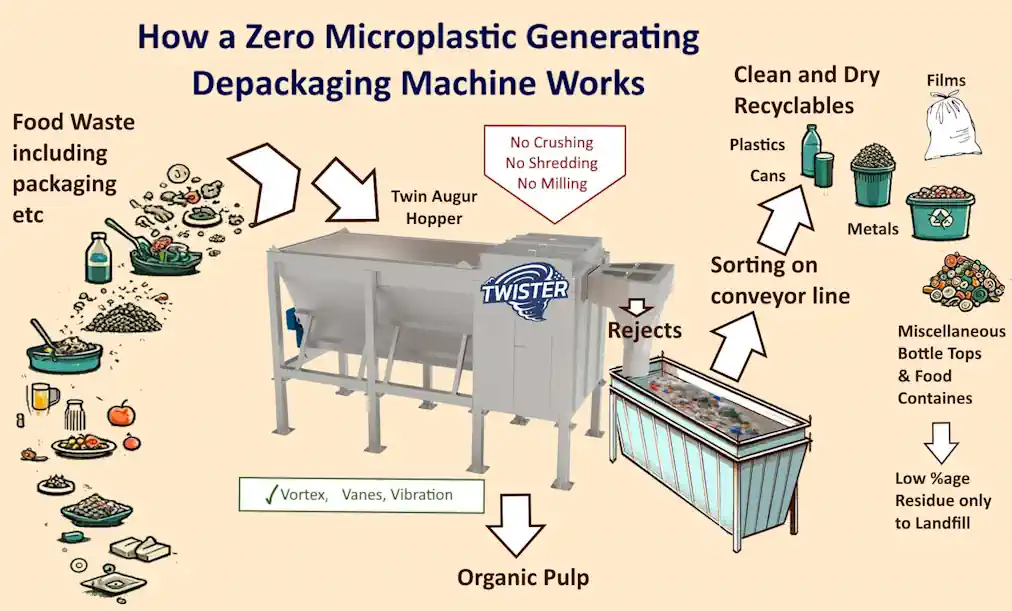

Mechanical separation uses machines like the Depackaging Machine DRM and the Twister by Drycake.

A Swiss study published in 2020 highlights the necessity of removing plastic films from biowaste to meet RAL quality standards for reusable plastic, and to do it cleanly with minimal organic matter, still adhering to the plastic. The commonly used methods utilised—traditional star sieves, drum sieves, and cross-flow air classifiers—demonstrate a significant technological disadvantage compared to modern, specialised depackaging and separation machinery.

The Efficiency Gap

The primary failure of these conventional pre-treatment systems lies in their inability to cleanly separate plastics from organic matter. By relying on basic mechanical screening and air classification, these methods inadvertently discard a massive portion of the valuable feedstock.

- Mechanical Limitations: Star and drum sieves lack the precision to “scrub” or detach adhering biowaste from plastic films.

- Contamination vs. Recovery: While the paper reports a 90% plastic removal rate, it comes at a staggering cost to the core objective of biowaste processing.

The Economic Threat to Anaerobic Digestion

The most critical takeaway from this data is the 30% loss of biogas potential caused by organic substances adhering to the separated plastic. In a modern circular economy, this level of inefficiency is unacceptable for several reasons:

- Jeopardized Viability: A 30% reduction in feedstock yield directly threatens the economic viability of Anaerobic Digestion (AD) plants. When nearly a third of the energy potential is sent to disposal or incineration along with the plastic “rejects,” the return on investment for the facility collapses.

- Superior Alternatives: Specialized depackaging machines (such as vertical centrifugal separators or high-torque paddle finishers) are designed specifically to liberate organic pulp from packaging. These machines achieve significantly higher recovery rates than the sieves and classifiers described in the text, ensuring that the “organic soup” remains in the digester rather than the landfill.

Bottom Line: Utilizing outdated separation methods is a “false economy.” Meeting RAL purity standards is moot if the process renders the extraction of organic content financially unsustainable through excessive loss of biogas yield.

The best depackaging machines are built from strong stainless steel, which allows them to handle tough tasks. This material and the separation method, as employed in the Drycake Twister avoids creating microplastics by ingeniously separating items based on size and material type—important for recycling plastic resins efficiently and reducing waste.

Particle size reduction

Depackaging still often involves shredding or crushing materials for particle size reduction. That creates microplastic, and now that the damaging effect on nature is known, particle size reduction is deprecated.

It also said that smaller particles make subsequent recycling processes more effective. This may have been true before the latest depackaging machines were developed, but now there are at least 5 manufacturers that sell machines with superior performance.

Nowadays, the so-called “rejects stream that contains mostly plastic can only be placed onto a general waste picking conveyor if discrete bottles, not tiny plastic chips of microplastic, are created.

Advanced separation techniques for minimal impact

Advanced separation techniques help separate the non-organic materials from waste with as little damage as possible to the plastic items, and without creating extra problems like microplastics. The Drycake Twister machine offers high-purity separation, which is crucial for processing mixed organics like food waste.

These techniques use mechanical separation by the use of a perimeter screening system and an air vortex to sort the organic materials from other waste components effectively. Vortex depackagers similar to those used in the Drycake Twister separate the non-organic packets, packages, and other particles from the organic ones, improving the efficiency of recycling processes and lowering landfill waste.

This makes resource recovery more efficient whilst maintaining low environmental impacts.

Benefits of Efficient Depackaging

Enhanced resource recovery and income from recyclates, not least plastic resins

Depackaging technologies that create a clean rejects stream boost resource recovery. They separate valuable recyclates like plastic resins with high purity. 3rd generation, Twister depackaging machines help achieve this by sorting waste efficiently, capturing every usable bit.

The organic portion of the depackaged food waste can then be processed in anaerobic digesters or composted.

This process reduces landfill use and methane emissions while generating useful biogas and biosolids for fertilisers. Enhanced recovery means more income from selling recyclable materials, supporting a circular economy where nothing goes to waste—every piece finds a new purpose or form.

Reduction in landfill waste

Efficient depackaging technologies help reduce landfill waste. Separating food waste from its packaging means less non-biodegradable material ends up buried. This frees space in landfills and decreases pollution.

Wastewater treatment facilities use these technologies to manage municipal solid waste better. By processing wasted food, they cut down on harmful methane emissions.

This makes the world cleaner and greener while supporting a circular economy.

Conclusion

Depackaging technologies help sort and recycle waste efficiently. Advanced processes like mechanical separation and particle size reduction improve resource recovery. The largest and best of these machines handle up to 25 tonnes per hour with or without adding extra water, making them very efficient.

They reduce landfill waste and support clean energy production through co-digestion of food scraps with wastewater sludge and organics from agricultural wastes. Machines with robust stainless steel construction ensure long-lasting performance in demanding tasks.

FAQs

1. What are efficient depackaging technologies?

Efficient depackaging technologies separate packaging from organic waste cleanly, helping reduce food loss and waste.

2. How do these technologies help in recycling?

They allow the recovery of materials like plastics for resin pellet recycling, aiding landfill diversion and promoting circular economies.

3. Can depackaging technologies handle kitchen wastes?

Yes, they process kitchen wastes efficiently, making them suitable for anaerobic digesters or biogas plants.

4. Do these technologies contribute to clean energy production?

Absolutely! They support biogas production by providing clean feedstock for anaerobic digestion processes.

5. Are there benefits for sustainable businesses using these systems?

Indeed! Sustainable businesses can reuse separated materials beneficially and improve their environmental footprint.

6. What happens to the organic waste after depackaging?

The organic waste can be anaerobically digested, turned into biomethane or natural gas, or used in wastewater treatment facilities.

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.

I like this web blog it’s a master piece!

Glad I detected this.