Low-impact depackaging technologies are advanced mechanical systems designed to separate organic food waste from its packaging (plastic, metal, cardboard, glass tec) while keeping the packaging material largely intact. Unlike traditional shredding or grinding methods that create difficult-to-recycle microplastics, these modern systems—such as the Drycake Twister—maximize resource recovery for anaerobic digestion and composting while facilitating high-quality recycling of packaging materials.

Key Takeaways

- Advanced depackaging technologies can achieve up to between 95% and 99% organic recovery rates, significantly outperforming the 80-85% rates of traditional hammer mills and reducing landfill waste while producing cleaner outputs.

- Low-impact depackaging systems like horizontal and vertical rotating shaft separators and hydro-mechanical systems generate significantly fewer microplastics, addressing a key environmental concern for downstream applications.

- The return on investment for advanced depackaging equipment averages 2-3 years for high-volume operations when considering improved “product” quality, higher throughput, and reduced disposal costs.

- Operators can reduce contamination levels from 5-10% with traditional systems to less than 1% with advanced technologies, opening new markets for organic outputs in premium composting and anaerobic digestion.

- Drycake’s innovative depackaging solutions are designed to maximize resource recovery while minimizing environmental impact, making them a trusted partner for waste management professionals.

The task of separating food waste from packaging has become a critical issue. As landfills reach capacity and regulations become stricter, traditional depackaging technologies simply can’t meet the current demand for cleaner outputs and higher recovery rates.

Why Traditional Depackaging Methods are Outdated

Hammer mill and other “particle size reduction” depackaging and separation systems have been the industry standard for many years.

However, as sustainability standards increase, the shortcomings of these systems are becoming more and more apparent. These systems use fast-spinning hammers or the cutting action of knives to crush, chop, and cut everything in their path, including both organic material and packaging. This method is effective at opening packages, but it also makes tiny pieces of metal and plastic that are often invisible to the naked eye, and creates many problems further down the line.

The biggest problem with conventional systems is the production of microplastics. Hammer mills and similar particle size reducers don’t just separate packaging when they smash through it; they shred plastic into microscopic particles that pollute the organic output.

According to research from the EPA, traditional depackaging methods can produce plastic fragments as small as 150 microns—particles that are nearly impossible to remove completely once they have been created. Scott Equipment has also noted this through extensive field testing by the researchers at the University of Vermont (UVM). So, there can be no doubt that these microplastics reduce the quality of end products, whether it’s compost, digestate, or animal feed.

Aside from issues of contamination, conventional methods have difficulty with recovery efficiency. Hammer mill depackagers, which are the norm, usually recover organic material at rates of 80-85%. This means that up to 20% of valuable organic material is lost in the reject stream and ends up in landfills. This lack of efficiency results in a loss of potential income and higher disposal costs for operators in all areas of waste management.

Here are some of the problems with traditional depackaging methods:

- Too much microplastic contamination in the output

- Not enough organic recovery (usually only 80-85%)

- Too much energy use because of the need for brute force separation

- Not enough flexibility to handle different types of packaging materials

- Too much wear and tear and maintenance because of the high-impact operations

The industry has noticed these problems and has started to innovate new low-impact depackaging technologies. These new technologies are designed to specifically address these problems. The modern solutions now focus on gentle separation methods. These methods keep the organic fraction and the packaging materials intact.

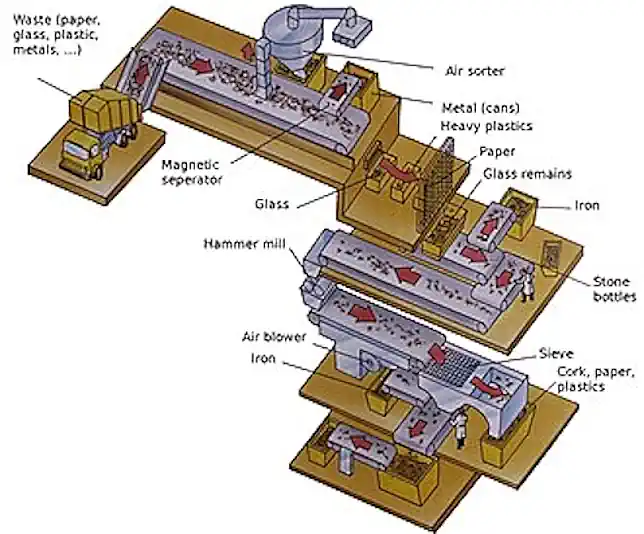

“Materials recovery facility – Wikipedia” from en.wikipedia.org and used with no modifications.

Four Innovative Depackaging Technologies Revolutionising Waste Management

Depackaging has come a long way in the last ten years, with four particular technologies standing out in the low-impact movement. Each one brings its own set of benefits, depending on the characteristics of the waste stream, the volume requirements, and the needs of the downstream processing. For more insights on these advancements, explore the food depackaging systems that are shaping the industry.

Microplastic-Reducing Alternative: Horizontal Shaft Separators

“Food Waste Depackaging Systems | BioCycle” from www.biocycle.net and used with no modifications.

Horizontal shaft separators are a notable improvement on traditional hammer mills. These systems use low-speed, high-torque augers or paddles to exert pressure instead of impact force, effectively “squeezing” organic materials out of packaging. The gentle crushing action preserves the integrity of most packaging materials, significantly decreasing the production of microplastics compared to high-speed impact systems.

Horizontal shaft systems regularly achieve recovery rates above 95%, with the best models reaching up to 97% organic recovery. This technology is particularly effective with challenging materials such as multi-layer packaging, tetra paks, and plastic-wrapped produce that often confuse traditional systems. In addition, the lower operating speeds result in reduced energy consumption—typically 30-40% less than hammer mill equivalents.

Vertical Shaft Depackagers: Speedy Recovery of Organics

“Horizontal shaft separators” from recyclinginside.com and used with no modifications.

Vertical shaft systems provide an interesting compromise between traditional and genuinely low-impact methods. These systems use vertical rotating parts that rely on centrifugal force instead of direct impact to separate materials. Despite operating at higher speeds than horizontal systems, their design reduces direct contact between hard surfaces and packaging, leading to significantly less fragmentation.

“Twister Food Waste and MSW Depackager …” from www.twisterseparator.com and used with no modifications.

Squeeze-Based Systems: The Solution for High-Contamination Waste Streams

When it comes to waste streams with high contamination levels, squeeze-based systems are a proven technology. These systems use hydraulic pressure to squeeze mixed waste between plates or inside chambers, which forces organic materials through screens while keeping packaging materials intact. Because of their ability to handle heavily contaminated inputs, including those with up to 40% non-organic content, squeeze-based systems are an invaluable tool for processing municipal solid waste and retail food waste.

Important Performance Metrics in Today’s Depackaging

It is crucial to look past what the manufacturers claim when assessing depackaging technologies. The industry has begun to standardize performance metrics to give a more accurate expectation of how the technology will perform in real-world applications. Waste management professionals can make better decisions that align with their operational goals by understanding these metrics.

Manufacturers may have impressive specifications, but the actual performance can vary greatly. This depends on the characteristics of the input, operating conditions, and maintenance practices. The most reliable evaluations come from pilot testing with your specific waste stream. You can also visit reference installations that process similar materials.

Looking Beyond the Marketing Hype: Organic Recovery Rate

The main metric to consider when measuring the performance of any depackaging system is the organic recovery rate. This is the percentage of organic material that the system successfully separates from its packaging. Modern low-impact technologies consistently achieve organic recovery rates of 92-97%, compared to 80-85% for traditional systems. While this may seem like a small difference, it can result in significant cost savings for facilities that process large volumes of material. For example, a facility that processes 20,000 tons per year could divert an additional 2,000 tons of valuable organic material from the landfill and turn it into a product that generates revenue by improving its recovery rate by just 10%.

Keeping Contamination Levels Low: What Really Counts

When we talk about contamination in the organic output stream, we’re referring to the percentage of non-organic materials (by dry weight) that are left after processing. The best low-impact technologies out there can keep contamination levels under 1%, and some hydro-mechanical systems can even keep them under 0.5% on a consistent basis. This is a critical factor in determining how marketable the end product is and how much it’s worth, whether it’s being used for composting, anaerobic digestion, or animal feed production.

Comparing Energy Use

As businesses strive to reduce their carbon footprint and operational expenses, energy efficiency is a top priority. Traditional high-speed systems typically use 50-75 kWh per ton processed. However, modern low-impact alternatives operate within the 30-45 kWh range. This represents energy savings of up to 40%. This efficiency is especially important for continuous operations processing large volumes. In these cases, energy costs can exceed $100,000 annually.

How Different Waste Types Affect Throughput

Throughput, or the number of tons processed per hour, can vary greatly depending on the type of equipment used and the characteristics of the waste stream. Most commercial depackagers can handle between 2 and 15 tons per hour, but some high-capacity systems can process up to 30 tons per hour for certain applications. Keep in mind that the moisture content, type of packaging, and level of contamination in your waste stream can all significantly affect the actual processing rate, so it’s important to take these factors into account when evaluating throughput claims.

Practical Uses for Low-Impact Depackaging

Today’s depackaging technologies are being used successfully in a variety of waste management sectors, each with its own set of needs and challenges. Seeing how these systems are used in specific applications can provide useful information for operations that are considering upgrading their technology.

Managing Waste in Food Production

Food production companies often grapple with issues such as expired items, production mistakes, and quality control failures, all of which necessitate effective depackaging for appropriate resource recovery. These waste streams usually consist of consistent packaging materials, but they can also contain difficult materials such as multi-layer films, foil-lined containers, or special barrier packaging. Horizontal shaft separators are useful in food production settings, achieving organic recovery rates of more than 95% while preserving the integrity of packaging materials for potential recycling.

Dealing with Waste from Grocery and Retail Food

When it comes to grocery and retail businesses, the waste they produce is highly unpredictable. It can range from rigid plastic containers to cardboard boxes and even flexible films. As such, they require depackaging systems that are highly versatile and can tolerate contamination. Vertical shaft depackagers are perfect for this job because they can handle the unexpected items that are often found in retail waste. This includes non-food contaminants like rubber bands, twist ties, and price labels.

Processing of Municipal Solid Waste

The processing of municipal waste is a significant challenge for depackaging technologies due to the extreme variability of the input composition and high levels of contamination. Hydro-mechanical systems have been more effective in these environments, using the ability of water to separate materials based on their density rather than relying solely on mechanical force. A number of European municipalities have used these systems as pre-treatment stages for anaerobic digestion, increasing biogas production by 15-20% and reducing the maintenance of downstream equipment by more than 30%.

The Financial Upside of Modernizing Your Depackaging Equipment

There’s a strong financial argument for investing in modern depackaging technology that goes well beyond the environmental benefits. Today’s systems offer significant economic benefits, with multiple income streams and operational efficiencies that just aren’t possible with older technologies.

Progressive operations always weigh the direct financial implications and indirect benefits such as decreased maintenance, improved employee safety, and better regulatory compliance when considering potential upgrades. A thorough analysis usually shows that modern systems yield positive ROI within 2-3 years, despite their higher initial investment costs.

ROI Analysis: When Higher Initial Investment Pays Off

Modern low-impact depackaging systems usually require a 30-50% higher initial investment compared to old-fashioned hammer mill technologies. But when you consider the total cost of ownership over a 5-7 year operational lifespan, the financial analysis changes dramatically. Facilities that process more than 10,000 tons per year typically get a full return on investment within 24-36 months thanks to increased organic recovery, higher-value outputs, and lower disposal costs.

Maximizing Profits with High-Quality Organic Outputs

Modern depackaging systems produce remarkably clean organic outputs that are highly sought after in the marketplace. Compost facilities are willing to pay an additional $5-15 per ton for organic material with less than 1% contamination. Anaerobic digesters are also willing to pay a premium of $10-20 for low-contamination feedstocks that won’t harm their systems. For a medium-sized facility processing 15,000 tons per year, these premiums could result in an additional annual revenue of $75,000-$300,000.

Aside from the cost benefits, clean outputs open up completely new market opportunities that are not available to operations using traditional depackaging methods. Production of animal feed, premium soil amendment manufacturing, and specialized biochemical production all require exceptionally pure organic inputs that only modern separation technologies can consistently provide.

Saving Money in Operations

Low-impact technologies, which use a gentle separation approach, have been shown to offer significant savings in maintenance costs compared to high-impact systems. Facilities that have made the switch have reported reductions in maintenance costs of between 35% and 50%. This is mainly due to less wear and tear on important parts and less frequent screen replacements. These savings can typically add up to between $30,000 and $75,000 per year for medium-sized operations.

Another significant cost benefit of modern systems is their energy consumption. The typical reduction in energy requirements by 30-40% can result in annual savings of $15,000-$40,000 for continuous operations. There are also added benefits such as reduced peak demand charges and the potential to qualify for energy efficiency incentives from utility providers.

Choosing the Best Depackaging Technology for Your Business

Choosing the best depackaging technology involves a careful evaluation of your specific operational needs, waste stream characteristics, and business goals. Following a systematic approach will help you find the technology that offers the most value for your specific needs.

Step 1: Get to Know Your Waste Stream Composition

The first and most important step in choosing the right technology is to conduct a thorough waste audit to understand the exact composition of your input materials. You’ll want to record the percentage breakdown of packaging types (rigid plastics, films, metals, glass, etc.), moisture content ranges, and common contaminants. This analysis should also take into account seasonal changes and expected future changes to ensure that the technology you choose will still be effective as your waste stream changes.

Step 2: Figure Out How Much You Need to Process

Knowing how much you need to process will help you avoid getting a machine that’s too small (and causes problems in your operations) or too big (and costs too much). Figure out how much you’re processing now in tons per hour and tons per day, then add 20-30% more to make sure you can handle growth and peak times. Think about both average and maximum times to make sure the machine you pick can handle it when things get busy without slowing down.

Step 3: Assess Space and Installation Limitations

Contemporary depackaging systems differ greatly in their physical size and infrastructure needs. The majority of commercial systems necessitate 500-1,500 square feet of floor area, plus extra clearance for material handling equipment, maintenance access, and reject collection. Vertical shaft systems usually have the smallest footprint, while hydro-mechanical systems require extra space for water management components.

Aside from space, you should also assess your facility’s electrical capacity, availability of water (for hydro-mechanical systems), and structural requirements. Many facilities discover that retrofitting existing spaces for modern depackaging equipment necessitates substantial infrastructure upgrades, which should be included in the project budget.

- Ceiling height requirements (typically 12-20 feet minimum)

- Floor load capacity (systems often weigh 5,000-20,000 pounds)

- Electrical service (most systems require 3-phase power)

- Ventilation and odor control infrastructure

- Material handling pathways for inputs and outputs

Working with an experienced equipment provider like Scott Equipment can help identify potential installation challenges early in the planning process, preventing costly surprises during implementation. Their engineering team can conduct detailed site assessments to ensure compatibility with your existing infrastructure.

Step 4: Determine the Total Cost of Ownership

Don’t just focus on the initial buying price, but also consider the long-term costs associated with the technology. Ask manufacturers for detailed information about typical maintenance needs, consumable parts schedules, energy usage under different operating conditions, and the expected lifespan of key components.

When you take the time to look at the total cost of ownership (TCO), you need to consider how much labor is required for operation and maintenance, utilities, when parts need to be replaced, how much downtime will cost, and what will happen when the machine reaches the end of its life. When you look at the big picture, you often find that technologies that cost more at the outset actually cost less over their lifetime because they are more efficient and require less maintenance.

Step 5: Think About How Your Depackaging System Will Work With Your Other Processes

After your depackaging system has done its job, the output needs to be able to work with the rest of your processes. You’ll need to think about the specific needs of your composting operation, anaerobic digester, or other systems. Things like particle size, how wet the output is, and how much contamination is acceptable all need to be able to work with whatever comes next in your process. The best manufacturers can change the output to fit your specific needs, making sure everything works as well as possible.

Adapting to Compostable Packaging

With the rise of compostable packaging, depackaging manufacturers are responding by creating technologies that can distinguish between conventional and compostable materials. These systems use sensors to detect PLA, PHA, and other compostable polymers, which can then be directed to the organic output stream instead of the reject pile. This feature will become more and more important as consumer brands move towards compostable packaging due to environmental concerns and regulatory demands.

Flexible and Expandable System Designs

The future of depackaging systems is all about flexibility and expandability to meet the needs of growing operations and ever-changing waste streams. Instead of having to replace an entire system as volumes increase, these designs allow facilities to add processing capacity in stages. This method reduces the risk of capital investment and allows operations to test out technologies with a lower initial commitment before scaling up. Many manufacturers now offer systems that can start at 2-3 tons per hour and grow to 15+ tons through modular additions, providing a viable option for growing operations. For more insights on the future of these systems, explore emerging technologies and innovations in the field.

It’s Time for an Upgrade: A Step-by-Step Guide to Transitioning to Modern Depackaging Technology

Switching to modern depackaging technology is not a decision to be made lightly. It requires careful planning and execution to ensure minimal disruption to operations and to maximize the return on investment. A successful transition usually follows a six-month timeline from the initial assessment to full operation.

Start with a comprehensive waste audit and a demonstration of the equipment using your actual materials. Next, get the buy-in of internal stakeholders by showing them the clear financial and operational benefits. Work with equipment providers who have experience and offer turnkey installation services, and who provide comprehensive training for operators. If possible, plan for a phased implementation.

This will allow your team to become proficient with the new system before ramping up to full production volumes. Finally, establish clear performance metrics and regularly review the results against expectations to optimize the operation of the system.

Common Questions

Waste management professionals often have a number of questions when assessing depackaging technologies, particularly in terms of performance, capabilities, and operational considerations. The answers provided here are based on practical experience and information provided by manufacturers.

Having a solid grasp of the practical applications of depackaging technology allows operators to set achievable goals and adequately prepare for successful implementation. While there is no one-size-fits-all solution, modern systems can provide solutions for almost any waste management scenario, provided they are chosen and operated correctly.

What makes modern depackaging systems less likely to produce microplastics than hammer mills?

Modern depackaging systems are designed to reduce the creation of microplastics by using different mechanical principles. Instead of using high-speed impact to break down packaging like hammer mills, these low-impact technologies use controlled pressure. This allows the packaging to stay intact while the organic contents are extracted. By using this gentler method, microplastics aren’t created in the first place, so there’s no need to remove them later. For more insights, explore industrial depackaging solutions that boost efficiency and sustainability.

Which waste streams are most difficult for depackaging equipment to handle?

Multi-layer flexible packaging is the most difficult for all depackaging technologies to handle because it tends to tear instead of separating cleanly. Materials such as stand-up pouches, coffee bags, and some snack packaging combine several types of polymers with layers of aluminum, resulting in fragments that closely resemble organic material in both size and density when shredded. Similarly, packaging with strong adhesives, like fruit labels or tamper-evident seals, often requires specialized processing to achieve clean separation.

Products packaged in glass present their own set of problems, mainly because of the risk to safety and possible damage to equipment. Although most modern systems can cope with a small amount of glass, it is advisable to use specialized glass-handling depackagers for waste streams that contain over 10-15% glass packaging. These systems have extra safety measures and stronger components to deal with glass fragments in a way that is safe for operators and won’t damage downstream equipment.

What is the typical floor space needed for a modern depackaging system?

Depending on the processing capacity and technology type, a full depackaging system generally needs 500-1,500 square feet. This includes the main separation equipment, input and output conveyors, control systems, and required maintenance access space. Hydro-mechanical systems usually need the largest footprint due to additional water management components. However, vertical shaft systems often provide the most compact installation options for facilities with limited space.

Can low-impact depackagers process both dry and wet packaged waste?

Most modern systems can be adjusted to accommodate different moisture levels by modifying operating parameters such as processing speed, pressure settings, or screen configurations. This flexibility allows facilities to handle seasonal changes in waste composition without sacrificing performance. Some manufacturers offer specialised configurations for predominantly wet or dry applications to optimise separation efficiency for specific waste streams.

For operations with highly fluctuating moisture content, the most versatile solution is a hybrid system that combines several separation technologies. These systems can guide materials through different processing paths based on their moisture characteristics, ensuring that each type of waste is handled in the best possible way. While these hybrid approaches are more complex and costly than solutions that only use one technology, they perform better for facilities that handle a variety of waste streams. For those looking to enhance efficiency and sustainability, exploring industrial depackaging solutions can be a valuable step.

Ensure you test any equipment you’re considering for mixed-moisture applications with both your driest and wettest materials. This will show you how the equipment performs across the full range of your operation and prevent any nasty surprises once the equipment is installed. It will also help you make sure the system you choose meets your specific needs.

What are the maintenance requirements for facilities with newer depackaging technologies?

Newer depackaging systems usually need 4-8 hours of planned maintenance every week, which is a lot less than the 10-15 hours that traditional hammer mills typically require. This maintenance mainly involves inspecting and cleaning the screen, lubricating moving parts, and checking wear components. Most manufacturers suggest replacing wear parts every quarter, regardless of how they look, although the actual replacement intervals can vary depending on how long the machine is operating and the characteristics of the material.

Remote monitoring and diagnostic capabilities are becoming increasingly common, allowing manufacturers to troubleshoot problems and provide guidance without on-site visits in many cases. For those interested in the latest advancements, exploring emerging technologies and innovations in depackaging can provide valuable insights.

Like any piece of industrial machinery, a strict preventative maintenance program can significantly prolong its lifespan and maintain optimal performance.

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.