Dealing with food waste is a big problem for many companies and cities. Tons of expired, spoiled, or discarded food end up in landfills every day. This leads to environmental harm and lost opportunities for recycling.

Modern depackaging machines can help solve this issue. They separate organic waste from packaging materials, making it easier to recycle or compost the waste. The organic waste, often known as pulp or “soup”, then has a value when used as a feed for anaerobic digestion plants and for composting

In this article, we will look at some of the best depackaging machines on sale in 2026. We will explore their features, pros and cons, and how they can help manage food waste better…

Read on!

Key Takeaways

- Modern depackaging machines help solve food waste issues by separating organic materials from packaging with high efficiency rates (95-99%).

- The Dominator Depackaging Machine offers up to 30m³/hr capacity, customisable motors, and gentle agitation to reduce microplastics.

- Tiger HS-90 processes up to 40 tonnes of organic waste per hour without requiring water, ideal for large-scale operations.

- Ecoverse® HS-30 and HS-55 models provide flexible solutions for both wet and dry materials. They cater to small and large spaces efficiently.

- The Drycake Twister is the best depackaging machine in our opinion. The range may not provide quite such a high throughput in 1 unit as some, but actual throughputs depend heavily on the type of waste treated for all machines. It provides all the features of the competitor models, not least the ability to “run dry” with no added water.

Understanding Depackaging: Its Importance and Impact

Over 30% of food waste reaches processing facilities still in packaging. This waste, often pre-consumer or post-consumer, ends up contaminating landfill sites. Depackaging machines remove packaging from organic matter before it’s processed further.

They have separation efficiency rates between 95-99%.

Reducing contamination is crucial for biogas plants and composting systems. Modern depackaging equipment can recover 90-99% of organic material. This means fewer microplastics—common in conventional methods—pollute the environment.

The Twister Depackager excels with a separation efficiency greater than 99%, showcasing why advanced depackagers are vital.

[Transparency Note: Drycake Sponsors this website. However, at all times, we endeavour to provide a balanced view of the products described. As editor, I am enthusiastic about the Drycake Twister and related Drycake products.]

Twister Depackager & Separator by Drycake – Vertical Cyclonic Vortex Separation Excellence

Twister Depackager & Separator by Drycake represents one of the most advanced depackaging technologies available in 2026, integrating patented vertical cyclonic separation that reimagines how packaged food waste and organics are pre-processed for recycling, composting, or anaerobic digestion. This system stands out for its non-shredding separation process and exceptional output purity — making it a compelling choice for operators seeking high performance and low downstream contamination.

Why Twister Is a Market Leader

Vortex-Driven Separation – Unlike traditional rotary blades or shredders, Twister uses a cyclonic vortex effect to separate organic material from packaging materials (plastics, cans, Tetra-Pak, glass, cardboard) without size reduction, preserving material integrity and reducing microplastic creation. In simple words, The main feature includes a spinning column of air that stretches from the bottom up. It is generated by the rotation of a vertical screw.

The result is that it provides cleaner and drier output from the Drycake patented bag-shredding technology.

High Purity Outputs – The unit consistently delivers ultra-clean organics (typically <0.5% contamination) and dry, recyclable packaging rejects, enhancing both downstream processing (e.g., compost quality, AD feedstock) and value recovery streams.

Versatile Feedstock Handling – Twister handles a broad spectrum of streams, from source-separated organics (SSO) and supermarket waste to municipal organic fractions (OFMSW) and packaged post-consumer food waste — enabling flexible deployment in municipal, commercial, and industrial settings.

Operational Efficiencies – With a small footprint, low energy demand, and minimal maintenance philosophy, Twister can be integrated directly ahead of composters, digesters, or waste processing lines without the need for pre-shredding equipment.

Key Benefits for Buyers

Reduced Disposal Costs: By maximising organic recovery and minimising mixed rejects, Twister can significantly reduce landfill disposal fees and lower operational costs.

Recycle-Ready Rejects: Packaging materials exit the unit largely intact and suitable for recycling streams — increasing revenue potential for recovered plastics, metals, and fibres.

Improved AD & Compost Feedstock: Clean, contaminant-free organic outputs enhance biological treatment processes and final product quality, making Twister ideal for facilities targeting high methane yields or premium compost products.

Twister by Drycake isn’t just another depackaging machine — it’s a complete pre-treatment solution that combines high recovery efficiency with operational simplicity. For operations that prioritise purity, sustainability, and long-term ROI in their waste management and organics recovery systems, Twister merits a close look.

Next, let’s explore the Dominator Depackaging Machine by Rowan Food and Biomass Engineering…

Dominator Depackaging Machine by Rowan Food and Biomass Engineering

The Dominator Depackaging Machine excels in handling various types of food waste. It separates organic material from packaging, making it ideal for recycling and landfill diversion.

Key Features and Innovations

Dominator Depackaging Machine by Rowan Food and Biomass Engineering stands out in waste management. It has several key features and innovations.

- High Purity Levels: Outputs reach a purity level of 99.94%. Independent testing verifies this claim.

- Five Base Models: Available models include 1800, 2000, 2500, 3000, and 3500. Throughput capacities go up to 30m³/hr.

- Customisable Motor Power: Motor power ranges from 15kW to 75kW. This allows for flexibility based on needs.

- Gentle Agitation Mechanism: Uses rotating paddles for gentle agitation. This reduces the generation of microplastics in the process.

- Local Manufacturing: Made in the U.K., supporting local industries while meeting global demand.

- Trial Machine Available: You can test waste processing capabilities at their Cheltenham headquarters before making a purchase.

These innovations make the Dominator an excellent option for reducing landfill waste and promoting environmental sustainability through efficient separation equipment.

Pros and Cons

Depackaging machines play a vital role in waste management, especially for food waste and other mixed waste streams. Here’s a breakdown of the pros and cons of these machines in a simple HTML table format:

| Pros | Cons |

|---|---|

| Customisable base models with varying throughput capacities (4m³/hr to 30m³/hr) | Potential costs for on-site trials borne by the customer |

| Versatile construction options (carbon steel or stainless steel) | |

| Capable of processing a wide range of waste types (food waste, pharmaceuticals, metals, plastics) | |

| Multiple configuration options (standalone, end-to-end line, compact all-in-one) | |

| Trial machine available for testing at the company’s headquarters |

Now, let’s explore the Dominator Depackaging Machine by Rowan Food and Biomass Engineering…

Tiger HS-90 Depackager: Your Solution for High-Volume Food Waste

The Tiger HS-90 Depackager stands out for handling large amounts of food waste quickly. It’s designed for businesses that need efficient waste processing.

System Capabilities and Specifications

The Tiger HS-90 Depackager offers top-notch performance for your waste management needs. It is built to handle high-volume food waste efficiently.

- Capacity

- Processes up to 40 tons of organic waste per hour.

- Handles both wet and dry organics in a single pass.

- Operating System

- Features an integrated CAN-Bus operating system.

- Makes automatic adjustments for optimal performance.

- Discharge Options

- Offers dual organic discharge options.

- Allows for slurry or dry/semi-dry organics discharge.

- Water Requirements

- Requires no water for operation.

- Includes solenoid valve controls to manage this feature.

- Availability of Demonstrations

- Demonstrations available upon request, allowing you to see the machine in action before purchase.

This machine is ideal for large-scale waste processing projects and suitable for various organic waste types, from food production scraps to expired food items. With its advanced technology and flexible options, it stands out in the environmental processing equipment market.

Ecoverse® HS-30 and HS-55 Models: Versatility in Food Waste Management

The Ecoverse® HS-30 and HS-55 models offer flexible solutions for managing food waste. These machines handle both pre-consumer and post-consumer waste, ensuring efficient disposal….

Comparison of Features and Efficiency

Comparing the features and efficiency of the Ecoverse® HS-30 and HS-55 models can help determine the best fit for your needs. Below is a detailed comparison table:

| Feature | Ecoverse® HS-30 | Ecoverse® HS-55 |

|---|---|---|

| Design | Compact, stationary | Flexible, meets regulatory demands |

| Processing Capability | Wet and dry materials in a single pass | Large-scale operations |

| Organic Waste Separation | Efficient separation from inorganic packaging | More thorough separation |

| Discharge Options | Dual discharge: slurry or dry/semi-dry | Advanced discharge options |

| Space Requirements | Suitable for limited spaces | Requires more space |

| Regulatory Compliance | Excellent for small to medium operations | Comprehensive compliance for large facilities |

| Support and Demonstrations | Available in North America | Available in North America |

Next, we’ll delve into the Dominator Depackaging Machine by Rowan Food and Biomass Engineering.

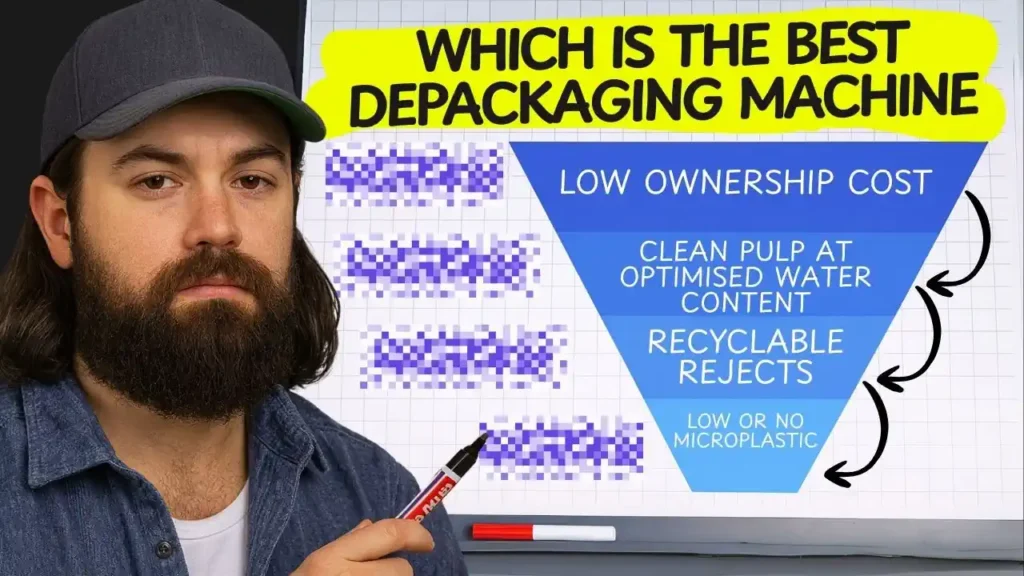

Conclusion: Choosing the Right Depackaging Machine

Selecting the best depackaging machine in 2026, as a depends on your needs. No single machine will be best for all organic wastes, and all installations.

The Dominator offers high purity levels with gentle agitation.

Tiger HS-90 is applauded for handling large volumes of food waste.

Ecoverse models provide flexibility and solid support. Each has unique features—pick the one that suits your operation!

However, despite Drycake sponsorship, we consider that for all source-separated organics the Twister should at least be considered as a front-runner.

For a more detailed understanding of the significance of depackaging in waste management, please visit our comprehensive guide on depackaging.

FAQs

1. What are the best depackaging machines for anaerobic digestion in 2026?

The top depackaging machines for anaerobic digestion in 2026 focus on handling both pre-consumer and post-consumer food waste efficiently. They convert spoiled food into organic pulp, aiding biogas production and supporting a circular economy.

2. How do these machines contribute to climate change mitigation?

Depackaging machines help reduce methane emissions by diverting packaged food waste from landfills to recycling or composting processes. This supports renewable energy efforts and reduces reliance on fossil fuels.

3. Are there compact options available with a small footprint?

Yes, several models offer a small footprint suitable for businesses with limited space. These compact machines are ideal for processing municipal solid waste and other recyclables without taking up much room.

4. Do these machines provide a good return on investment (ROI) for sustainable businesses?

Yes, investing in advanced agricultural machinery that handles biowastes can lead to significant ROI through improved efficiency in waste recycling processes—ultimately contributing to more sustainable business practices.

References

- https://twisterseparator.com

- https://elegantlyorganic.co.uk/depackaging-machines-food-organic-waste-separation/ (2024-10-26)

- https://wastersblog.com/103134/characteristics-depackaging-machine/ (2024-02-24)

- https://www.dominator-depackaging.com/solutions/machines/

- https://rowanfoodandbiomass.com/links/

- https://www.ecoverse.net/brands/tiger-depack/hs-90-depackager/

- https://www.ecoverse.net/brands/tiger-depack/hs-30-depackager/

- https://www.biocycle.net/food-depackaging-the-systems/

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.