Waste is a big problem. Every day, we throw away food and other items. This creates heaps of garbage in landfills. But what if there was a way to reduce this waste?

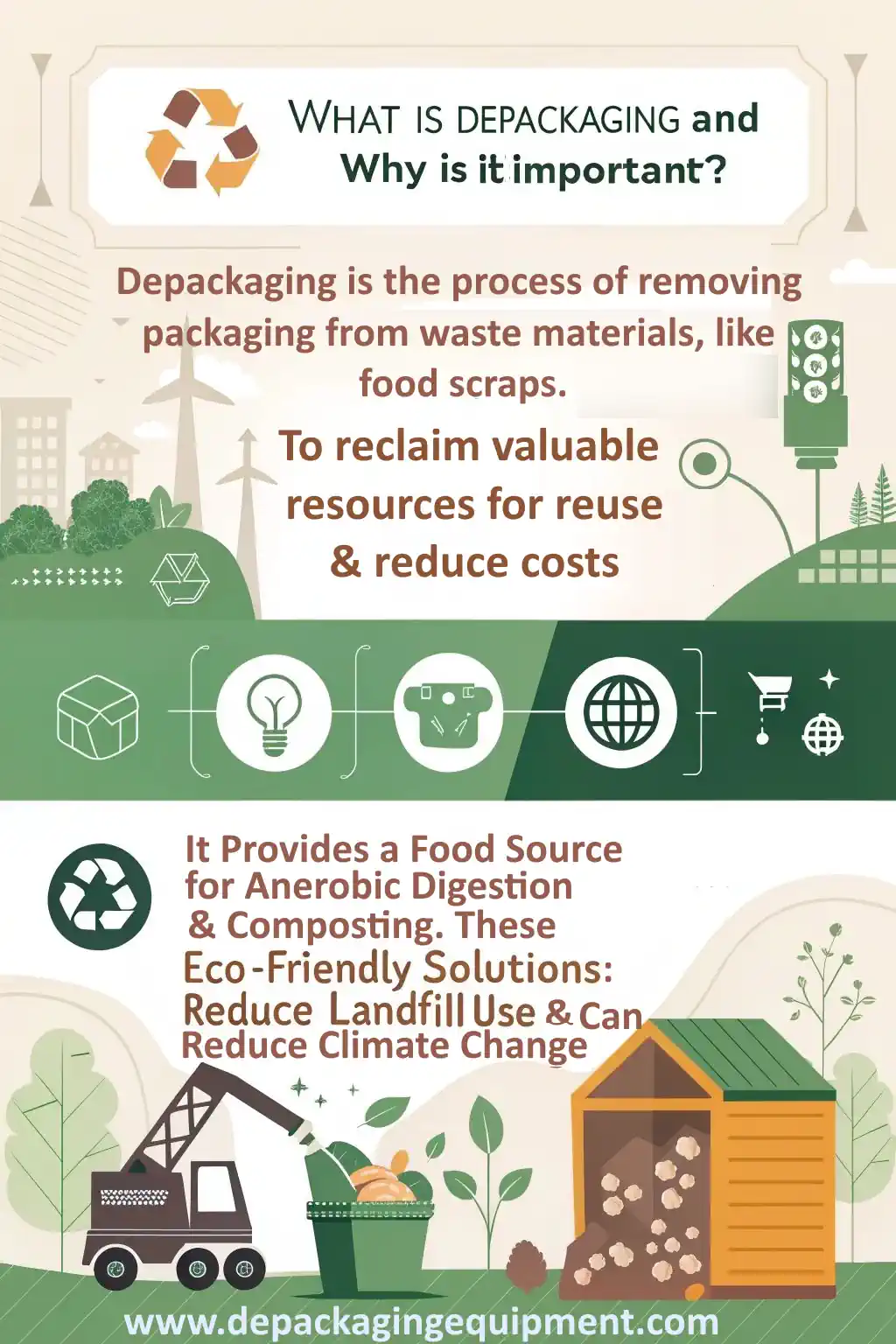

Depackaging can help! Depackaging is the process of removing packaging from waste materials, like food scraps and expired retail products. This helps separate the organic material from the non-organic parts.

In this article, you will learn about depackaging techniques and their benefits for waste management. Discover how it reduces landfill contributions and enhances recycling efficiency.

Let’s explore why depackaging matters!

Key Takeaways

- Depackaging removes packaging from waste, helping to recycle or reuse materials. This reduces landfill use and methane emissions.

- Machines like the Turbo Separator can process up to 30 tons per hour. They help separate recyclables efficiently.

- Technologies such as high-efficiency separators improve recycling by removing plastics from organic material. This boosts composting and biogas production.

- Depackaging supports sustainable practices by cutting down landfill contributions and reclaiming valuable resources for reuse.

- Automated systems like the ECRUSOR™ reduce operating costs and water usage, making waste management more eco-friendly.

Key Processes in Depackaging

Depackaging involves removing packaging from waste so we can recycle or reuse the contents. This process is vital for improving recycling rates and reducing landfill use.

Mechanical Separation Techniques

Mechanical separation techniques often involve shredding or crushing waste in tanks. This process breaks down packaging materials, separating them from the organic waste inside. The resulting semi-liquid biomass becomes perfect for anaerobic digestion or composting.

One popular system is the screw press, which helps to squeeze liquids out of solid food wastes efficiently. These methods may have high costs for equipment and maintenance but are crucial for effective waste recycling.

According to experts, “Mechanical methods play a key role in dividing packaging from organic matter.

Advanced Sorting and Screening

Advanced sorting and screening techniques are vital in depackaging. Using these methods, we can separate different types of waste more efficiently. Screening helps remove non-biodegradable items like plastics from organic matter.

This is important to avoid creating microplastics. Technologies such as the Drycake Twister enhance recycling efficiency by ensuring that only recyclable materials end up in the proper channels.

High-efficiency separators play a key role too. They sort waste quickly and accurately, boosting overall productivity in waste processing plants. These tools help manage food waste effectively, reducing landfill contributions and supporting resource conservation.

Advanced sorting technologies also prepare waste for anaerobic digesters, which generate renewable energy while cutting down methane emissions from landfills.

Best Mechanical Depackaging Systems for Waste Processing

[HTML Content 2]:

The Turbo Separator by Scott Equipment Company stands out in the recycling industry. It processes 50-200 tonnes of packaged organic waste daily, making it ideal for both small and large operations.

Different models can cater to various sizes, ensuring flexibility.

Another effective system is from Gemidan Ecogi. These machines efficiently tackle expired grocery products and restaurant waste. Food waste depackagers even achieve up to 97 per cent recovery and purity rates—impressive numbers for reducing landfill contributions!

Different Types of Waste Suitable for Depackaging

Depackaging can handle a variety of waste types. This includes common items like food and industrial products, ensuring efficient sorting for recycling or disposal.

Food Waste in Packaging

Food waste often comes in bags, boxes, cans, or bottles. In fact, over 80% of food waste is found in some form of packaging. This makes depackaging vital for separating the food from its wrapper.

Depackaging helps recover valuable materials. Machines like the DODA Bioseparator are efficient and can achieve recovery rates between 90-97%. By removing plastics and other contaminants, we make sure only organic material goes to composting or biogas plants.

This reduces landfill contributions and boosts recycling efficiency.

Industrial and Retail Products

Industrial and retail products often come heavily packaged, posing a challenge for waste management. Items like canned goods, cosmetics, and cleaning supplies generate significant plastic waste.

Depackaging these products is vital because it separates recyclables from organic matter.

Mechanical systems—like hammermills and shredders—are efficient in handling industrial packaging. These machines help reduce microplastic generation during the separation process.

Advanced depackaging techniques ensure that more recyclable materials are recovered… reducing landfill contributions.

Modern depackaging machines help us tackle plastic waste effectively, says an industry expert.

Properly managed reject streams contain less contaminated plastic, making recycling easier and more effective.

Importance of Depackaging in Waste Management

Depackaging helps reduce waste sent to landfills by separating useful materials from packaging. This increases recycling rates and supports a circular economy, making waste management more sustainable.

Reducing Landfill Contributions

Reducing landfill contributions is crucial. Depackaging helps achieve this by separating useful materials from waste. This separation decreases the amount of rubbish sent to landfills, cutting down on methane emissions.

Methane from landfills significantly contributes to global warming.

Collaboration among stakeholders boosts depackaging success. Waste management facilities, businesses, and governments must work together. Raising awareness about the benefits of depackaging can drive more sustainable practices in waste processing and recycling efficiency.

Enhancing Recycling Efficiency

Depackaging helps recycling by removing packaging from waste. This allows more materials to be recycled, reducing landfill contributions. Mechanical methods like shredding and crushing are used to separate items quickly.

Depackaging is crucial for improving the efficiency of recycling systems, says John Smith, a waste management expert.

Better recycling efficiency means more raw materials reclaimed and less greenhouse gas emissions from landfills. Enhanced biogas production from organic wastes also benefits agriculture practices through composting.

Technological Innovations in Depackaging Equipment

New machines now sort and separate waste with high precision. These systems use advanced sensors and robotics to handle different types of packaging.

Automated Systems

Automated depackaging systems use various methods like shearing, hammering, and pressure. These techniques help separate food waste from packaging quickly and efficiently. Scott Equipment’s THOR Turbo Separator can handle 2 to 40 tons of waste per hour with very little electricity.

Veolia offers another robust solution with its ECRUSOR™ system. It uses shaftless screw augers to puncture the packaging material. This method improves water efficiency and reduces operating costs—helping streamline the entire process while saving resources.

Automated systems are crucial for sustainable waste management practices.

High-Efficiency Separators

High-efficiency separators are essential in removing contaminants from organic waste. These machines capture plastics and other unwanted materials, leaving cleaner waste for recycling.

One standout model is the Twister Universal Depackager and Separator. It uses cyclonic technology to effectively separate organics from their packaging.

Investing in high-efficiency separators benefits facilities by improving compliance with environmental regulations. Cleaner waste means fewer issues down the line. This leads to enhanced recycling efficiency and supports sustainable practices.

Challenges in the Depackaging Industry

Handling contaminated waste is one major challenge. Compliance with environmental regulations also poses difficulties… These factors can slow down depackaging processes and increase costs for businesses.

Handling Contaminated Waste

Handling contaminated waste is crucial. It can have severe effects on health and the environment. Depackaging must tackle this challenge effectively. Advanced separation techniques help manage contamination.

Operational best practices improve safety and efficiency during handling. Regular training for staff ensures they follow protocols strictly. Using automated systems reduces human contact with hazardous materials, improving food safety.

Proper waste disposal methods are vital, too. Contaminated materials should be handled using specialised equipment like high-efficiency separators or trommel screens. This prevents harmful substances from entering landfills, promoting a cleaner environment.

Using source-separated organics (SSO) aids in recycling efforts by isolating non-contaminated items. This enhances overall recycling efficiency while reducing landfill contributions significantly… ensuring a sustainable future for all!

Compliance with Environmental Regulations

Government interventions are key to promoting eco-friendly packaging. Financial subsidies, tax incentives, and strict regulations push businesses to adopt green practices. For example, Germany’s extended producer responsibility has significantly reduced packaging waste.

Current challenges include the excessive use of non-eco-friendly materials. Overcoming this means using more biodegradable or recyclable options in packaged foods and organics recycling systems.

These steps help reduce landfill contributions and enhance sustainability efforts across industries.

Economic and Environmental Benefits of Depackaging

Depackaging helps reduce waste costs for facilities. It also supports eco-friendly practices by increasing recycling rates and lowering landfill use.

Cost Savings for Waste Management Facilities

Investing in depackaging technology can save waste management facilities a lot of money. Companies avoid high landfill tipping fees by removing packaging from waste materials. This process helps reduce the volume that goes to landfills, leading to cost savings.

Using advanced recycling systems, facilities can reclaim materials and sell them for profit. Recycled products and enhanced sorting techniques boost overall efficiency, offering economic benefits.

Improving recycling processes through technology means less is wasted and more resources are recovered, benefiting both the environment and the facility’s bottom line.

Contribution to Sustainable Practices

Reduced landfill contributions often lead to significant cost savings for waste management facilities. These benefits also extend to broader ecological impacts….

Depackaging greatly aids sustainable practices. It reduces landfill waste, curbing harmful methane emissions and soil degradation. Processed food waste can become a valuable food waste slurry used in biogas digesters—producing energy while cutting down on chemical fertilisers.

This helps promote sustainable agriculture and boosts the overall health of our environment.

Advanced depackaging systems enhance recycling efficiency by separating packaging materials more effectively, contributing to zero waste goals. High-efficiency separators manage source-separated organics (SSO) without contamination, paving the way for better composting outcomes—like those achieved by Coker Composting & Consulting.

These innovations further reduce carbon footprints linked to solid waste disposal.

Conclusion

Depackaging helps in separating organic and non-organic materials. This process reduces landfill waste and boosts recycling efforts. Advanced technologies like the Tiger Depackaging System make this task more efficient.

By using these systems, we can save costs and protect our environment. With better waste management, the future looks greener for all.

Discover more about the best mechanical depackaging systems for waste processing to understand how they can transform your waste management strategy.

FAQs

1. What is depackaging?

Depackaging involves separating food waste from its packaging. This process helps in landfill diversion by ensuring that source-separated organics (SSO) are properly managed.

2. Why is depackaging important for grocery stores?

Grocery stores generate a lot of biowaste, including vacuum-packed and other packaged foods. Depackaging allows them to separate the waste efficiently, making it easier to recycle, reduce their environmental footprint and save money when they avoid paying landfill taxes.

3. How does depackaging aid in energy production?

By separating food waste from packaging materials like glass or expanded polystyrene foam, the organic matter can be used in composters or digestate systems for energy production through anaerobic digestion.

4. Can depackaging help reduce chemical fertiliser usage?

Yes! By converting biowaste into digestate through proper separation techniques using pumps, conveyors, and compactors, depackaged food waste can replace chemical fertilisers with natural alternatives.

5. What challenges exist in the depackaging process?

Challenges include managing the wide variety of other trash mixed with food packaging collected from kitchens and dealing with materials like nanoplastics or polypropylene.

References

- https://www.wwdmag.com/what-is-articles/article/33015283/what-is-food-waste-depackaging (2023-11-17)

- https://www.biocycle.net/food-depackaging-systems/

- https://depackagingequipment.com/depackaging/

- https://thinkviably.com/resource-library/what-is-food-waste-depackaging/ (2024-04-29)

- https://www.biocycle.net/food-waste-depackaging-systems/ (2019-07-10)

- https://wastersblog.com/101429/food-waste-depackaging-methods/ (2022-06-19)

- https://thinkviably.com/resource-library/costs-of-not-depackaging-food-waste/

- https://www.biocycle.net/food-depackaging-the-systems/

- https://blog.anaerobic-digestion.com/food-waste-separators-for-depackaging/

- https://www.mdpi.com/2071-1050/14/23/15866

- https://www.researchgate.net/publication/260313237_Costs_and_benefits_of_packaging_waste_recycling_systems

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.