Many recycling facilities struggle to separate packaged products from their contents. Old methods like size reduction and screening waste time and money. These methods also create a mess of mixed materials that need extra sorting. This makes it hard to meet strict recycling standards and environmental goals.

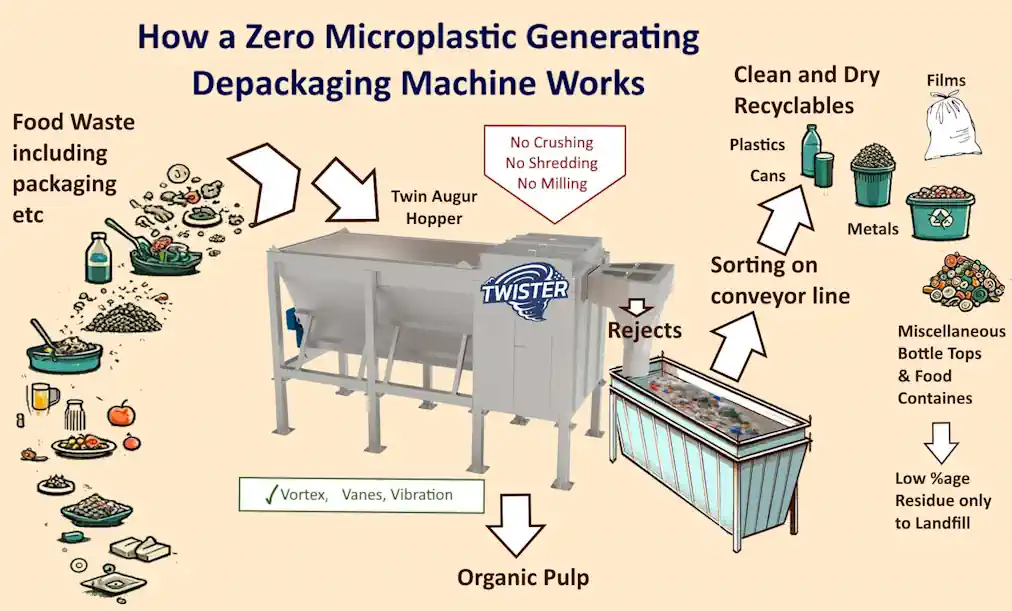

The latest generation of low-impact depackaging machines, such as those offered by Mavitec and Drycake, offer a solution to this challenge that avoids manufacturing huge tonnages of microplastic and nanoplastic in food waste recycling facilities. These machines can process up to 15 tonnes of packaged waste per hour with clean separation rates above 95%, and some above 98%.

Our guide explains the steps for integrating depackaging machines into your facility. You’ll learn how to choose the right equipment, train your staff, and maximise your investment. Ready to transform your recycling operations?

Key Takeaways

- Depackaging machines process up to 15 tonnes of packaged waste hourly with 95-99% separation rates. The Twister by Drycake achieves a remarkable 99.8% organic material removal rate from packaging materials.

- About 30% of food waste arrives at processing facilities still in packaging. Modern depackaging systems use paddles and screens to split food from packaging in one step, creating clean streams for biogas plants.

- These machines eliminate outdated size reduction methods like milling and screening. This prevents microplastic contamination whilst maintaining high-quality organic output for anaerobic digestion and composting.

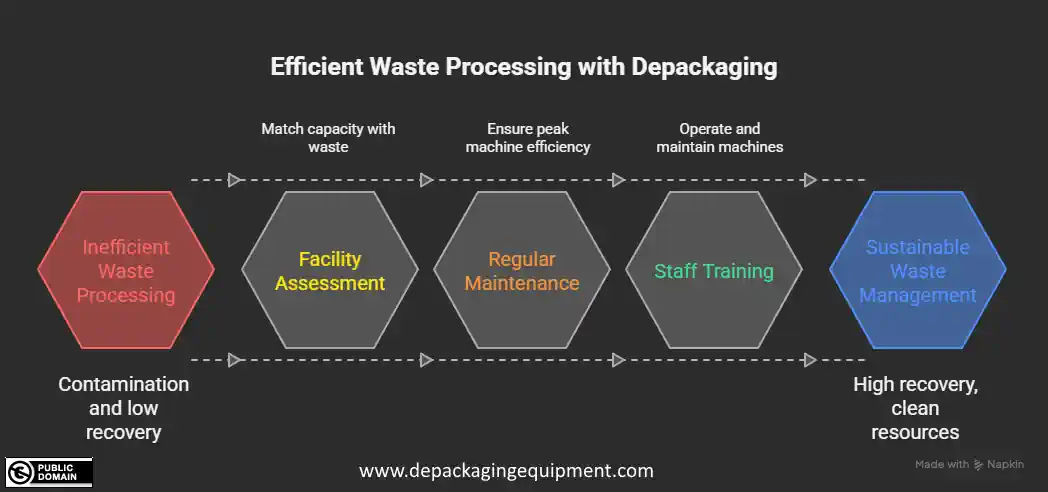

- Proper facility assessment must match machine capacity with waste volume. Key factors include available floor space, power supply, staff expertise, and material flow patterns. Regular maintenance keeps machines running at peak efficiency.

- Facilities report 40% higher material recovery rates after installing depackaging systems. The technology creates multiple revenue streams through clean organic pulp for biogas and separated packaging for recycling or fuel products.

Depackaging Machines for Separation of Organic Pulp and “Rejects” from Source-Separated Organic Waste

Modern depackaging machines excel at separating organic materials from packaging waste. The Twister by Drycake leads the market with a 99.8% organic material removal rate from packaging materials.

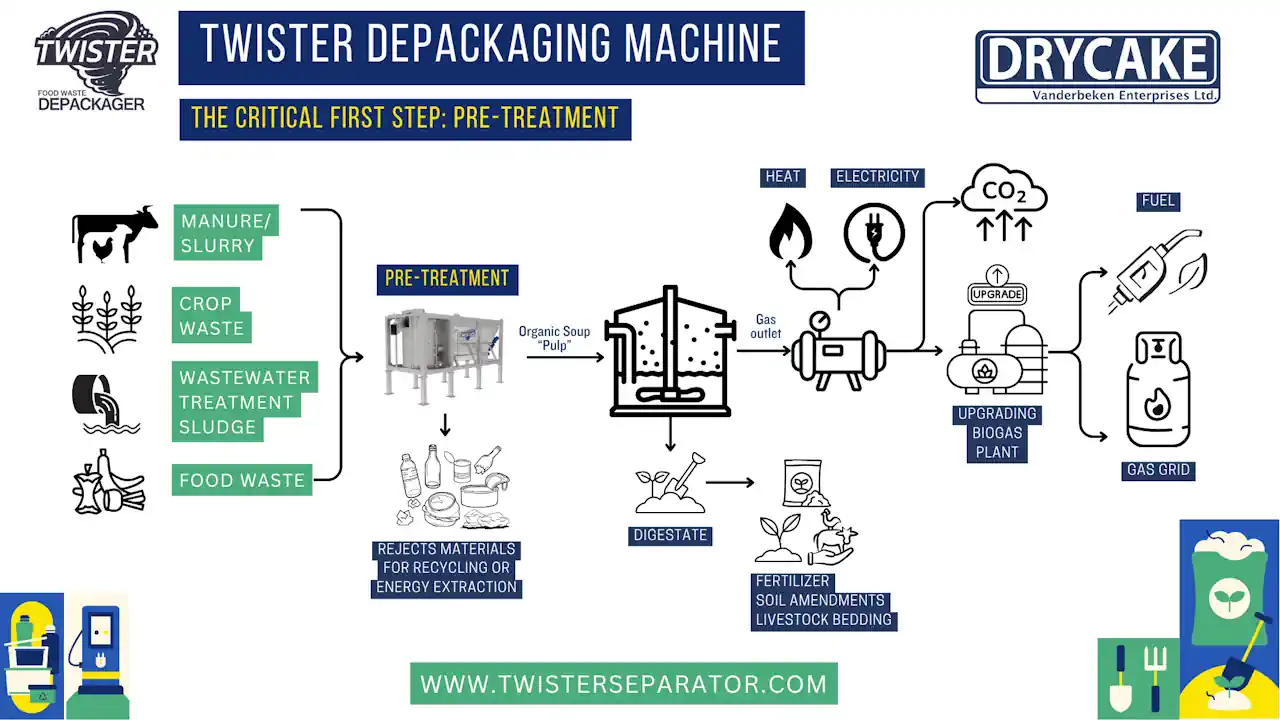

These machines process source-separated organic waste into clean pulp for biogas plants while removing unwanted items like plastic and metal.

Effective depackaging technology that retains the packets, tins, and cans, in big enough pieces to by picked out by smart sorting technology is the key to plastics recycling, and stands as the cornerstone of modern organic waste processing

Recycling facilities face a significant challenge with packaged food waste. About 30% of food waste arrives at processing facilities still in its packaging. 1 Depackaging machines solve this issue by breaking down the materials and creating two distinct streams: organic pulp for anaerobic digestion and rejects for alternative processing.

The technology supports strict regulatory requirements for managing microplastics while improving the purity of organic waste streams.

Depackaging Machines for Pretreatment of Organic Waste for Clean Plastic and Metals Free Biogas Digester Feed

Depackaging machines play a vital role in preparing clean organic waste for biogas digesters. These machines achieve separation rates of 95-99% for organic materials from packaging waste. 1 The Drycake Twister uses air vortex technology to separate materials without grinding, which stops microplastic contamination in the process. This advanced system processes 2-15 tons of waste per hour, making it ideal for large-scale operations.

The separated organic material flows directly into biogas digesters with optimal solids-to-water ratios. Clean feedstock improves digestion efficiency and creates better quality digestate for sustainable waste management.

The removal of plastics and metals ensures pure organic content for maximum biogas production. Staff training focuses on safe operation and routine maintenance procedures to maintain these high-performance levels.

The next section explores how depackaging machines handle various materials through their separation process.

Depackaging Machines for Creating SRF from the “Rejects” (Non-Organic content) Output Stream

Modern recycling facilities now turn non-recyclable plastics into Solid Recovered Fuel (SRF) instead of sending them to landfills. The Twister by Drycake leads this transformation with its 99.8% organics removal rate, creating high-quality reject streams perfect for SRF production. 2 Strict regulations have pushed facilities to stop landfilling these materials, making SRF conversion a vital solution for waste management.

The shift to SRF production offers recycling facilities a new revenue stream while supporting sustainable practices. Advanced separation technologies help remove microplastics from waste outputs, meeting stricter environmental standards. 3 This process diverts materials from landfills to energy recovery systems, cutting greenhouse gas emissions. The next step involves understanding how to plan the integration of these machines into existing facilities.

Why Size Reduction (Milling and Screening etc) is Obsolete as an Organics Separation Technology

Size reduction methods like shredding and milling create serious problems in organic waste processing. These old techniques increase microplastic contamination in the organic output stream. 2 Traditional crushing methods also make it harder to separate clean organics for anaerobic digestion. The process leads to higher costs through increased landfilling of non-organic rejects.

New depackaging technologies focus on gentle separation without size reduction steps. These systems protect the quality of source-separated organics while preventing microplastic formation.

Direct separation delivers better solids-to-water ratios for biogas production. The clean organic output serves as a valuable digestate fertiliser, if subsequently windrow composted, for sustainable agriculture. Operators now favour low-impact separation to maintain high purity in organic waste streams. 4

How do depackaging machines separate packaging from contents?

Depackaging machines use powerful paddles and screens to split food from its packaging in a single step. The machines produce two clean streams:

- organic pulp for biogas plants and

- dry materials, such as plastic or metal, for recycling.

How do depackaging machines handle expired or damaged products?

Modern depackaging machines break open packages of expired or damaged products through mechanical force. The best of these machines extract food contents from various packaging materials with high precision.

The mechanical separation keeps organic materials clean and free from non-compostable items. Food waste from supermarkets and processing facilities flows smoothly through these systems for maximum resource recovery. 5

Staff safety improves as the machines reduce direct contact with spoiled products. The extracted organic materials create pure feedstock for composting or biogas production. The process maintains strict quality standards for downstream waste treatment.

The next step involves planning the right integration strategy for your facility’s specific needs. 6

How do depackaging machines process different materials?

Depackaging machines handle various packaging materials through a specialised rotary system. The machines use integrated blades and paddles to cut open, squeeze, shake and generally break open tin cans, drinks bottles, plastic bottles, Tetra-pak containers, and steel and aluminium cans, directing the organic pulp and all the non-organic materials into separate output streams.

These machines process soft and rigid packaging with equal efficiency. The system separates organic waste from packaging materials to produce clean, nearly contamination-free outputs for biodigesters and recycling facilities.

Effective depackaging technology serves as the cornerstone of modern waste management, turning mixed waste streams into valuable resources. 7

The Tiger depackaging system combines precise shredding and screening mechanisms for optimal material separation. This technology, like the others, processes multiple organic materials, including dairy products, produce, meat, and fish waste.

Smart sensors monitor the processing speed and adjust it based on the material type entering the system. The separated organics become valuable feedstock for anaerobic digesters, while clean packaging materials move to recycling streams.

Planning the integration of depackaging machines

Planning the right depackaging system needs clear goals and proper facility assessment. Your recycling facility must match the machine’s capacity with your waste volume while meeting safety rules and space limits.

How do I assess my facility’s needs for depackaging machines?

A proper assessment of your depackaging machine needs forms the backbone of successful waste management operations. Modern facilities must evaluate several key factors to make informed decisions about their depackaging equipment requirements.

- Review waste stream composition through detailed analysis of organic wastes, plastic content, and other materials received daily at the facility.

- Calculate processing capacity needs based on current waste volumes and projected growth over the next 3â5 years.

- Measure available floor space in the facility to ensure adequate room for machine installation and safe operation zones.

- Analyse material types handled at the facility to match them with compatible depackaging equipment specifications.

- Study current operational costs against potential savings from automated depackaging systems.

- Check existing control systems to determine integration requirements for new depackaging machines.

- Survey staff expertise levels to identify training needs for operating new equipment.

- Examine facility power supply capacity to support additional machinery load requirements.

- Map out material flow patterns to identify optimal placement points for depackaging units.

- Document current waste separation rates to establish baseline performance metrics.

- List specific packaging types processed to ensure machine compatibility with all materials.

- Assess maintenance resources available for regular equipment upkeep and repairs.

- Compare current waste reduction rates against target goals to determine required efficiency improvements.

- Monitor peak processing periods to plan for maximum capacity requirements.

- Record facility operating hours to calculate expected machine usage patterns.

How do I select the right depackaging machines for my requirements?

Selecting depackaging machines requires careful analysis of your facility’s specific needs and operational goals. Modern depackaging technology offers various options for waste management professionals to process source-separated organics efficiently. 1

- Match processing capacity to daily waste volumes through detailed waste stream assessment.

- Space requirements must align with your facility layout and allow proper machine installation.

- Cost analysis includes purchase price, operational expenses, and expected return on investment.

- Material compatibility testing ensures the machine handles all waste types in your stream.

- Technical support availability in your region affects maintenance schedules and downtime.

- Control systems need real-time monitoring features for optimal performance tracking.

- Integration capabilities with current facility systems maximise operational efficiency.

- Energy consumption rates impact operational costs and sustainability targets.

- Safety features protect staff during operation and maintenance tasks.

- Automation level suits your workforce skills and training resources.

- Parts availability ensures quick repairs and minimal disruption to operations.

- Equipment durability matches your facility’s operating hours and conditions.

- Compliance with local regulations guides machine specifications and permits.

- Output quality meets standards for downstream processes like biogas production.

- Maintenance schedules fit your facility’s operational patterns.

- Noise levels stay within acceptable workplace limits.

- Machine footprint allows proper access for cleaning and repairs.

- Operating costs align with your budget constraints.

- Training requirements match staff capabilities and time resources.

- Performance guarantees protect your investment and ensure reliable operation.

How can I plan installation and optimise workflow for depackaging machines?

Planning a depackaging machine installation needs careful thought about space and workflow. Smart integration of these machines can boost your facility’s waste processing capacity and reduce maintenance costs.

- Space assessment must include room for loading zones, sorting lines, and equipment access paths for source-separated organics processing. 9

- A waste audit helps track the exact types and amounts of food waste your facility handles each day.

- Clear goals must focus on improving waste stream handling and final product quality through proper depackaging.

- Machine placement requires direct access to waste input areas and close links to main sorting lines.

- Staff training programmes need to cover safety protocols and proper machine operation techniques.

- Infrastructure upgrades might include stronger floors, better drainage, or new electrical systems.

- Performance tracking systems help spot and fix any workflow problems quickly.

- Loading zone design must allow trucks to dump waste safely and efficiently.

- Regular maintenance schedules keep machines running at peak performance levels.

- Emergency protocols need clear marking and easy access to shut-off switches.

- Storage areas for processed materials require proper ventilation and containment systems.

- Clean-up procedures must follow strict health and safety guidelines.

- Documentation systems track daily processing volumes and machine performance metrics.

The next crucial step involves training your staff to operate these depackaging machines safely and efficiently. 5

How can staff be trained to operate depackaging machines safely and efficiently?

Staff need clear safety protocols and hands-on practice with depackaging machines to master the loading, operation, and cleaning steps – read on to learn the essential training methods that boost workplace safety and machine efficiency.

What are the key maintenance procedures for depackaging machines?

Proper maintenance keeps depackaging machines running at peak efficiency. Regular upkeep prevents costly breakdowns and extends equipment life. 1

- Daily machine inspections check for loose bearings, worn parts, and unusual noises in the auger system

- Weekly cleaning removes food waste residue from all contact surfaces using approved sanitising agents

- Monthly wear assessments examine critical components like pumps and extraction mechanisms for signs of damage

- Performance log updates track operational data and maintenance activities for compliance purposes

- Feed rate calibration ensures optimal processing speed without overloading the system

- Cleaning protocols focus on removing trapped organic matter from screens and filters

- Quarterly bearing lubrication maintains smooth operation of moving parts

- Safety equipment checks verify emergency stops and protective guards work properly

- Annual professional servicing includes complete system overhaul and parts replacement

- Temperature monitoring prevents overheating during continuous operation

- Belt tension adjustments maintain proper material flow through the system

- Waste container inspection ensures proper seal and prevents leakage

- Screen cleaning removes buildup that could affect separation efficiency

- Motor maintenance includes checking oil levels and electrical connections

- Sanitisation procedures follow applicable standards for handling organic waste

Next, we explore how depackaging machines improve efficiency in recycling facilities through automated separation processes.

Benefits of integrating depackaging machines

Depackaging machines boost your recycling facility’s performance through improved waste sorting and higher material recovery rates. These machines create new revenue streams from source-separated organics while meeting strict environmental standards for biomethane production and circular economy goals.

How do depackaging machines contribute to waste reduction?

Efficient recycling leads to effective waste reduction through depackaging machines. These machines process several tons of waste per hour, which cuts down landfill volumes. The separation of food waste from packaging creates pure organic pulp for composting.

Depackaging machines support source-separated organics (SSO) programmes in waste management. The machines separate expired products from supermarkets and food processing waste into clean organic waste streams, ideally suited for feeding into high methane output biogas digester tanks.

High-purity organic materials go to biogas plants or, where allowable under local waste regulations, to composting sites. Meanwhile, the separated packaging materials become renewable fuel or recycled products. This system reduces plastic pollution and keeps food waste out of landfills.

In what ways do depackaging machines help save costs?

Depackaging machines create major cost savings through reduced waste disposal fees. Food waste processing costs drop because these machines separate organic materials from packaging with high accuracy. The water content adhering to the plastic films and rigid packets is also reduced.

Companies raise their sustainability record while avoiding environmental pollution, and the global warming damage linked to methane emissions from rotting food waste in landfills. In short, the machines produce clean organic outputs, which cuts downstream waste management expenses. 7

Mobile depackaging solutions help smaller facilities process waste right on site. This cuts transport costs and labour needs for waste handling. The machines handle various expired packaged foods at high speeds, boosting facility throughput and return on investment.

Staff can focus on other tasks while the automated systems work. Next, we’ll explore how these machines support sustainability targets through renewable energy production. 10

How do depackaging machines support sustainability goals?

Modern depackaging machines support vital sustainability targets through efficient waste separation. These machines convert food waste into sellable, sustainable products while reducing landfill usage.

The Tiger Depackaging System processes multiple tons of waste per hour, creating high-quality organic pulp for biogas production. This process aids the circular economy by turning waste into renewable energy. 5

Sustainable depackaging equipment handles diverse waste streams with precision, cutting microplastic pollution in oceans.

This supports source-separated organics (SSO) processing and helps tackle climate change through reduced emissions. The next section explores how these machines assist with meeting regulatory requirements in waste management facilities.

Conclusion

Depackaging machines mark a new era in waste management with better recycling rates and reduced landfill waste. Modern recycling facilities need this technology to process food waste and create renewable energy from organic materials.

Thoughtful integration of depackaging machines forms a critical part of waste recycling success. Each facility needs a clear plan to match its specific operational goals and waste streams. 12 Strategic placement of equipment creates smooth workflows in the recycling process. Staff training plays a vital role in the proper use of these machines for food waste separation.

The right integration approach leads to better efficiency and compliance with waste management rules. 12 Facilities must review their processes often to maintain top performance levels.

Regular checks help spot areas that need improvement. Smart implementation of depackaging systems boosts return on investment through reduced landfill costs and increased renewable energy production from organic waste.

FAQs

1. What is a depackaging machine, and how does it help with recycling?

A depackaging machine, like the Twister Separator and Depackager, removes packaging from food waste and other materials. It helps separate items like plastic bags and containers from organic waste, making both materials ready for proper recycling.

2. Can depackaging machines handle different types of waste?

Yes, modern depackaging systems can process various materials, including biscuit waste in packaging, kitchen waste, and post-consumer trash that would typically end up in sanitary landfills.

3. How do depackaging machines support environmental goals?

These machines make recycling more environmentally friendly by reducing landfilled waste and supporting renewable energy production through biogas generation from food waste.

4. What safety measures should staff follow when operating depackaging equipment?

Operators must wear proper protective gear and follow user-friendly operating procedures to ensure safe waste processing.

5. How does a Drycake Seditank system benefit recycling facilities?

The Drycake Seditank helps facilities manage biowastes effectively, removing persistent foreign matter before it enters a biogas digester or commercial composting pile, preventing it from polluting natural gas systems while supporting construction of renewable energy projects.

6. What regulations apply to depackaging machine operations?

Facilities must follow waste processing facility guidelines and operational protocols suggested by the Renewable Energy Association while ensuring proper composting and recycling of plastic materials.

References

- ^ https://elegantlyorganic.co.uk/depackaging-machines-food-organic-waste-separation/

- ^ https://recyclinginside.com/recycling-technology/size-reduction/why-food-waste-depackagers-prioritize-microplastics-avoidance-over-size-reduction/ (2022-06-24)

- ^ https://www.birmingham.ac.uk/documents/college-eps/energy/publications/energy-from-waste-policy-commission-report-2020.pdf (2020-01-23)

- ^ https://wastersblog.com/101638/food-waste-depackaging-equipment-suppliers-technologies/ (2022-06-19)

- ^ https://www.ecoverse.net/blog/how-depacking-machines-improve-the-food-composting-process/

- ^ https://waste-technologies.co.uk/in-depth-analysis-how-does-food-waste-depackaging-and-separation-equipment-works/

- ^ https://depackagingequipment.com/organic-waste-depackaging-machines/

- ^ https://www.researchgate.net/publication/361910659_Food_Waste_Depackaging_and_Separation_Functions_and_Recent_Industry_Advances_Depackaging_and_Separator_Functions

- ^ https://thinkviably.com/resource-library/how-to-implement-food-waste-depackaging-into-commercial-composting/ (2025-01-24)

- ^ https://www.kenbay.com/depackaging (2016-10-13)

- ^ https://waste-technologies.co.uk/the-role-of-food-waste-depackaging-and-separation-equipment/

- ^ https://www.researchgate.net/publication/378316050_A_Comprehensive_Study_on_Quality_Management_and_Sustainability_in_the_Field_of_Packaging (2024-02-20)

- ^ https://depackagingequipment.com/industrial-depackaging-solutions-boost-efficiency-sustainability/

- ^ https://wastersblog.com/103134/characteristics-depackaging-machine/ (2024-02-24)

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.