Dealing with food waste using Mechanical Depackaging Systems is a big challenge. Many places struggle to handle waste properly because packaging can be hard to separate from the food. This problem can make composting and recycling harder.

Did you know that depackaging systems help solve this? They remove the packaging from food waste, making it easier to recycle to a biogas plant for energy production and compost. Mechanical Depackaging Systems help reduce the amount of waste going into landfills by allowing it to be diverted to biogas production or composting sites for compost product production.

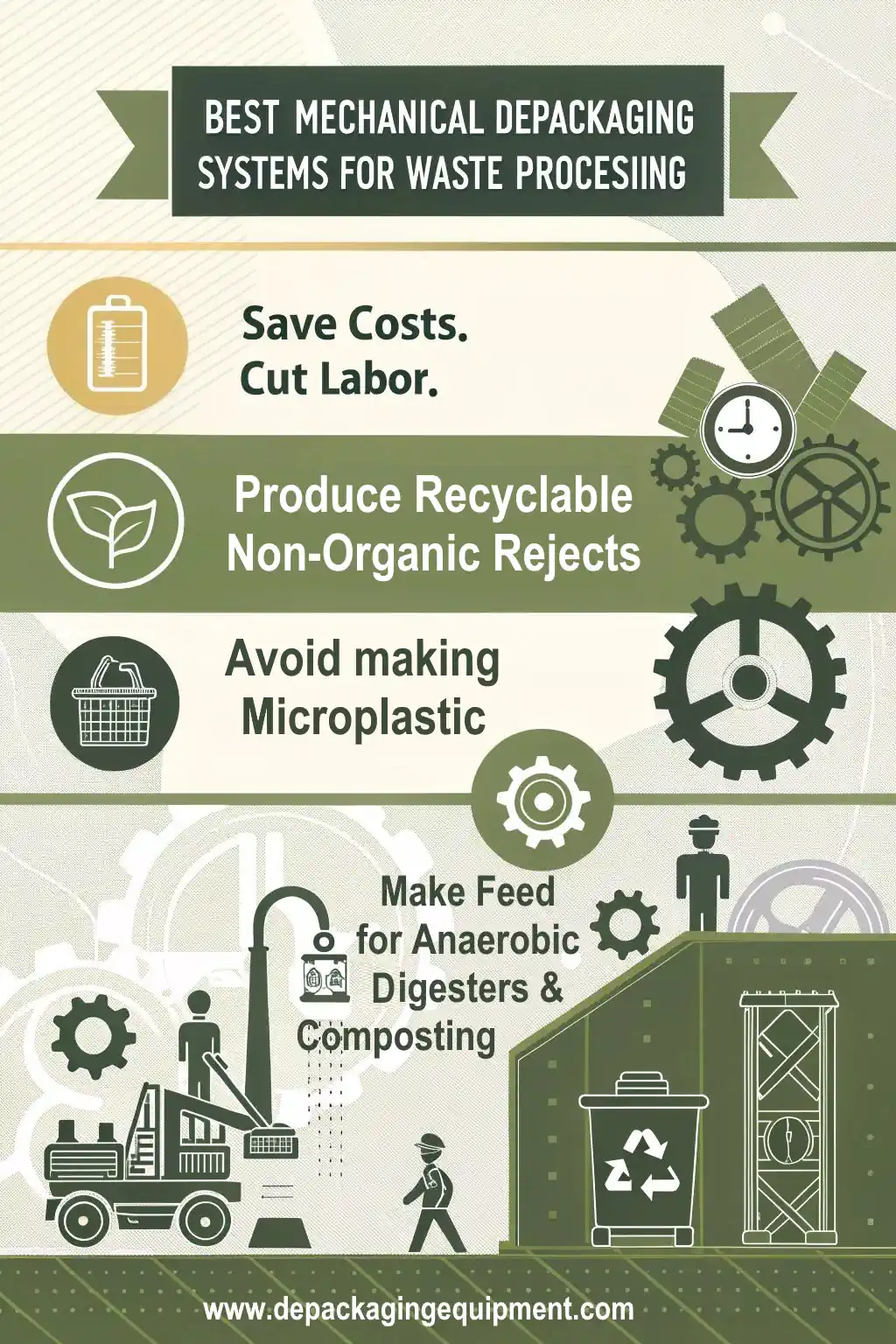

In this blog, we will look at different types of mechanical depackaging systems. You’ll learn about their benefits, technologies, and top features. Keep reading… there’s much more to discover!

Key Takeaways – Depackaging Systems

- Depackaging systems save costs and time. They reduce landfill fees and cut labour by up to 12 hours daily.

- These machines improve food safety. Automation lowers the risk of contamination from human handling.

- Examples like the largest Turbo Separator can process up to 200 tons per day, making them ideal for large facilities.

- New AI-powered depackaging tech offers 99% accuracy in sorting the reject plastic, tin cans etc., separated from food waste, subsequently boosting recycling efficiency on MRF and ERF conveyor lines.

- Laws pushing for reduced food waste drive demand for these systems, enhancing compliance and reputation.

Key Benefits of Implementing Depackaging Systems

Depackaging systems can save costs by reducing landfill fees and improving waste separation. They also boost operational flexibility, making processes more efficient.

Cost Reduction

Automation in depackaging systems slashes labour costs. These machines sort packaging from food waste, saving up to 12 hours of work daily per location. Companies can dodge landfill fees and avoid expensive disposal methods.

Waste processing becomes cheaper with fewer workers needed. Depackaging also cuts down on transportation costs, as separated waste is easier to handle and move. With less manual sorting, efficiency goes up – meaning more savings overall.

Depackaging saves us thousands yearly, says a waste management expert.

Enhanced Food Safety

Mechanical depackaging systems boost operating technician safety by reducing manual sorting. This lowers the risk of contamination from human handling. Denali’s process ensures compliance with food waste disposal rules, meeting both local and national standards.

Such steps improve the overall quality of recycled materials and make them safer for use in sustainable agriculture practices.

Increased Operational Flexibility

Mechanical depackaging systems give businesses more ways to handle waste. These systems are adaptable and can work with different types of materials like metals, plastics, and pharmaceuticals.

For example, the Drycake Twister Depackager and Separator can operate without added water, on many dry organic waste streams making it versatile for various settings.

Depackaging technology also allows companies to adjust processes quickly. The Dupps-Mavitec system features adjustable paddle angles to optimise separation based on the material being processed.

This flexibility helps facilities switch between tasks smoothly, reducing downtime and increasing efficiency.

Employee Satisfaction and Safety

Automation in depackaging systems boosts worker safety. Machines handle the tough tasks, reducing injuries. Denali customers see 4 to 12 hours of labour saved each day at each site.

Workers feel valued when they have a safer work environment. Happy employees are productive and stay longer with the company.

Safety comes first for us, says Jane Doe, Waste Management Director.

Recycling industry experts note that automated systems lead to fewer health risks. This makes waste processing more efficient and reliable for everyone involved.

Compliance and Reputation Enhancement

Depackaging systems help meet local government regulations and food waste disposal rules. Denali’s depackaging services ensure compliance with local and national laws where they operate. This keeps companies within legal standards and avoids costly fines.

Using these systems also improves a company’s image. Showing a commitment to sustainability can boost brand reputation. It makes people see the company as responsible and eco-friendly.

This is especially important in today’s world, where customers value sustainable practices.

Implementing effective depackaging also lessens landfill diversion rates, helping the environment by reducing waste going to landfills.

Leading Technologies in Food Waste Depackaging

Modern technology plays a huge role in waste depackaging. These machines can handle different packaging materials, making food waste recycling more efficient.

Metal Tin Can Depackaging Machines

Metal tin can depackaging machines recover both liquid and foodstuff contents from tin cans. This technology is essential for waste processing, ensuring that valuable resources are not wasted.

The Dominator Depackaging Machine excels in this area, efficiently separating metal from other materials.

Recycled metal from these machines contributes to the circular economy by reusing packaging materials. Interested buyers can see a trial machine at Cheltenham headquarters. Seeing it in action helps potential users understand its efficiency and benefits firsthand.

Recovered metal and content boost recycling efforts, says an expert at Gemidan Ecogi.

These machines support anaerobic digestion plants by separating useful organics from inorganic packaging—enhancing biogas production while reducing landfill waste.

Pharmaceutical Depackaging Machines

After discussing Metal Tin Can Depackaging Machines, let’s shift focus to pharmaceutical depackaging machines. These machines excel at separating organic material from packaging in food waste processing.

They have high recovery rates, ranging from 90% to 99%. Advanced tech helps minimise contamination in composting and anaerobic digestion facilities.

Water often boosts the separation process’s effectiveness. The biomass extracted is sent to anaerobic digesters or composting systems for biogas and biosolid generation. Proper disposal of non-biodegradable packaging is crucial for sustainable waste processing—enhancing overall efficiency and environmental impact.

Plastic Bottle Depackaging Machines

Plastic bottle depackaging machines get top marks for producing high-purity organic pulp. This pulp is perfect for anaerobic digestion. These machines meet the demand for efficient food waste solutions, boosting market growth.

Key features to look for include low energy use, reliability, and compact designs. Efficient plastic bottle depackaging reduces harmful microplastics in our environment, aiding climate change mitigation efforts and decreasing methane emissions from landfilled waste products.

Evaluation of Top Mechanical Depackaging Systems

Evaluating mechanical depackaging systems involves looking at their features and capabilities. These machines must be efficient and reliable to handle various types of waste packaging.

Features and Capabilities

Mechanical depackaging systems offer top features like efficiency, versatility, and durability. For example, the Twister™ Depackager produces zero microplastic fragments. This enhances recycling efficiency and keeps the environment clean.

These machines are user-friendly and safe for workers. They handle various waste types like metal tin cans, plastic bottles, and pharmaceuticals. The systems ensure smooth operation without frequent breakdowns—saving both time and money for companies.

They also support compliance with environmental laws, boosting your company’s reputation.

Efficiency and Reliability

Features and capabilities play a crucial role, but efficiency and reliability ensure smooth operations. The Turbo Separator by Scott Equipment Company shines in this area. It achieves more than 99% clean organics output—impressive reliability for waste management professionals.

Turbo Separator models process between 50 to 200 tons of packaged organic food waste per day. This high capacity boosts operational efficiency. Reliable systems like these help meet strict environmental regulations while enhancing recovery and purity, essential for biogas plants and municipal solid waste management.

Efficient Wet Depackaging Solutions for Various Industries

Efficient wet depackaging solutions help industries manage waste better. The Turbo Separator by Scott Equipment Company processes 50-200 tons per day. This machine separates food from packaging, making recycling and composting simpler.

Wet depackaging systems suit various fields like food production and pharmaceutical sectors. They handle different recyclables, from glass to plastic bottles. These systems reduce landfill waste and support sustainable business practices.

Using wet depackaging equipment also ensures high safety levels for employees while boosting operational flexibility.

Challenges in Food Waste Depackaging

Depackaging food waste faces several challenges—such as dealing with technical issues and environmental worries. Read more to understand these intricacies.

Navigating Technical Limitations

Technical limitations can challenge depackaging systems. Machines must handle up to 30% contamination in food waste. This high level of contaminants like plastic, metal, and paper makes the process hard.

Keeping machines well-maintained is key. Regular checks help ensure efficiency and reliability. Even a small fault could halt operations, leading to downtime and cost issues. Maintenance is crucial for smooth operation—preventing failure before it happens saves money and time.

Addressing Environmental Concerns

Food waste in landfills releases methane, a harmful gas. Depackaging systems help by diverting this waste. They separate source-separated organics (SSO) from packaging materials like plastic and metal.

Using compostable materials instead of single-use plastics lowers environmental impact. These efforts reduce reliance on fossil fuels and chemical fertilisers, promoting a sustainable future.

Effective depackaging ensures recyclable materials are reused, minimising garbage and over-consumption.

Case Studies: Success Stories in Depackaging

This section highlights real-world examples where depackaging systems made a big difference – discover how businesses handled food waste better, saved money, and boosted efficiency!

Example of Effective Implementation in a Meat Department

A meat department used the Tiger depackaging system to separate food waste from packaging. The system reduced contamination and improved waste processing efficiency. Denali also provided customised solutions for handling meat waste, enhancing sustainability.

These systems have proved successful in various facilities. They help in managing scraps effectively, ensuring zero waste goals are met. Using such technology, departments can comply with regulations and improve their reputation while reducing costs and environmental impact.

Impact on Large-scale Facilities and Campuses

The Turbo Separator by Scott Equipment Company is ideal for large-scale facilities. It can process food waste efficiently. With models handling capacities from 50 tons per day to 10-30 tons per hour, it suits big campuses well.

These systems help reduce landfill greenhouse gas emissions and support sustainability efforts.

Using effective depackaging solutions boosts operational flexibility and employee safety. Installing these systems also improves compliance with environmental regulations, enhancing the facility’s reputation.

For example, a campus using the Turbo Separator can manage waste better and contribute to renewable energy initiatives through biodigesters—reducing overall ecological impact significantly.

Future Trends in Depackaging Technology

New depackaging machines will focus on better efficiency and eco-friendly operations. Innovations may include smarter sensors, machine learning, and improved recycling methods to reduce waste further…

read on for more insights!

Innovations on the Horizon

AI-powered sorting systems are the big deal now. They show a 99% accuracy rate for spotting and sorting food waste. This tech helps reduce errors and speeds up work. The use of blockchain is another hot trend.

It will improve traceability in waste processing, ensuring that every step is transparent.

Wet depackaging solutions are also gaining traction across various industries—smoothly handling different types of materials like plastic, metal, and glass in one go. These innovations promise both efficiency and sustainability in managing biowastes…

all while meeting compliance regulations more easily!

Legislative Impacts on Technology Adoption

Laws in New Jersey, Oregon, and Washington aim to cut food waste by half by 2030. This drives demand for better waste processing technologies. Mechanical depackaging systems are a key solution.

New rules push businesses to adopt efficient machines like trommel screens and compactors. These help meet recycling goals without extra costs or hassles. Reduced waste means less incineration and lower environmental impact.

Compliance boosts reputation… hence attracting more customers!

Conclusion

Mechanical depackaging systems are crucial for effective waste processing. They boost efficiency, cut costs, and ensure safe food disposal. These technologies can tackle various types of packaging—making them versatile tools in waste management.

Adopting these systems leads to cleaner outputs and better compliance with regulations. So, invest in the best system to benefit both your operations and the environment!

For more information on how these technologies are advancing and their applications across different sectors, please visit our page on efficient wet depackaging solutions for various industries.

FAQs

1. What are the best mechanical depackaging systems for waste processing?

Mechanical depackaging systems separate packaging from source separated organics (SSO). They help in recycling and reduce rubbish going to landfills.

2. How do these systems handle different types of materials?

These systems can manage various materials like Tetrapak, recycled plastic, and even nanoplastics. Their compressive strength and hardness allow them to break down tough items.

3. Can these systems improve recycling transparency?

Yes, they offer detailed analytics on waste streams, helping manufacturers and suppliers understand what is being processed. This ensures better accountability.

4. Are there any videos or resources available for learning more about these systems?

You can find informative YouTube videos that show how different machines work in real-time scenarios, including their efficiency with waste receptacles.

5. Do mechanical depackaging systems support environmental sustainability efforts?

Absolutely! By separating out recyclables and reducing degradation of organic material, they contribute to producing cleaner composts without chemical fertilisers—promoting a healthier ecosystem overall.

References

- https://waste-technologies.co.uk/food-waste-depackaging-systems-for-sustainability-and-microplastic-reduction/

- https://thinkviably.com/resource-library/costs-of-not-depackaging-food-waste/

- https://www.wwdmag.com/what-is-articles/article/33015283/what-is-food-waste-depackaging (2023-11-17)

- https://thinkviably.com/resource-library/what-is-food-waste-depackaging/ (2024-04-29)

- https://www.biocycle.net/food-waste-depackaging-systems/ (2019-07-10)

- https://wastersblog.com/103134/characteristics-depackaging-machine/ (2024-02-24)

- https://www.denalicorp.com/services/depackaging/

- https://www.fpe.net.au/depackaging-machine/ (2023-10-20)

- https://www.dominator-depackaging.com/applications/metal-cans/ (2016-12-12)

- https://www.researchgate.net/publication/361910659_Food_Waste_Depackaging_and_Separation_Functions_and_Recent_Industry_Advances_Depackaging_and_Separator_Functions

- https://anaerobic-digestion.com/list-of-food-waste-depackaging-and-separation-equipment-suppliers/

- https://wastersblog.com/101429/food-waste-depackaging-methods/ (2022-06-19)

- https://pubmed.ncbi.nlm.nih.gov/29980332/

- https://www.closedlooppartners.com/wp-content/uploads/2024/03/3.19.24_CLP_ADCompostablePackagingWhitePaper_FINAL.pdf

- https://elegantlyorganic.co.uk/top-technologies-in-food-waste-separation/

- https://www.epa.gov/system/files/documents/2021-08/emerging-issues-in-food-waste-management-plastic-contamination.pdf

Discover more from IPPTS Depackaging Equipment Insights

Subscribe to get the latest posts sent to your email.